TangenX® SIUS® TFF Cassettes

SIUS® Cassettes are the first purpose-built single-use cassettes for tangential flow filtration, delivering unparalleled savings in filter cost, labor cost and buffer use.

TangenX® SIUS® Cassettes

Validated for GMP use, SIUS® TFF Cassettes are delivered ready to use with either ProStream or HyStream membranes, with choice of pore sizes and flow-channel configurations. Pre-sanitized and packaged with 0.2M NaOH, the cassettes are engineered with optimized channel geometry and enhanced device rigidity to ensure that hydraulic performance is maintained during processing and scale-up.

Click on the tabs below to explore different features of SIUS Cassettes for process development or commercial manufacturing.

During process development, the aim is to select the most promising membrane candidates while making related decisions regarding feed pressure, transmembrane pressure (TMP) and screen geometry. SIUS® PD single-use TFF Cassettes save valuable time and resources by eliminating cleaning cycles between experiments. Designed for processing volumes from tens of milliliters to several liters, SIUS PD Cassettes enable linear scale processing over a wide range of operating volumes.

Membrane Surface Areas:

0.01 m2, 0.02 m2, 0.10 m2

When the primary membrane candidate has already been chosen as a process parameter, the production method needs to be verified and production materials produced for toxicology or pre-clinical trials, and ultimately for large-scale commercial production. SIUS® Single-use TFF Cassettes provide reliable cassette-to-cassette consistency, ensuring that processes can scale to commercial production levels.

Membrane Surface Areas:

0.5 m2, 1.5 m2, 2.5 m2

TangenX® SIUS® Single-use TFF Cassettes are a convenient alternative to reusable cassettes. Delivered ready to use with choice of membrane, pore size and flow-channel configuration, SIUS Cassettes enable cost and process efficiencies while eliminating tedious clean-in-place (CIP) and sanitization steps because increased labor and consumables are not required.

SINGLE-USE EFFICIENCY

SINGLE-USE EFFICIENCY

Unparalleled process and cost efficiencies

TangenX® SIUS® Single-use Cassettes are the first purpose-built cassettes designed for tangential flow filtration. Deploying these innovative cassettes can help reduce filter cost by 80%, reduce labor costs by 50%, and reduce buffer and water usage by 75% when compared to traditional reusable cassettes.

HIGH PERFORMANCE UF/DF

HIGH PERFORMANCE UF/DF

Solutions designed to meet the needs of your process

SIUS® TFF Cassettes are offered with two membrane chemistries, two screen types and an open channel, a wide selection of molecular weight cutoffs (MWCO), and a broad range of surface areas. SIUS TFF Cassettes accommodate diverse process requirements for ultrafiltration and diafiltration applications from process development to commercial manufacturing.

| TangenX® SIUS® PD Cassettes | TangenX® SIUS® Cassettes | |

|---|---|---|

| Configuration | Single-use | |

| Membrane chemistry | ProStream, HyStream | |

| MWCO | 1 kD*, 3 kD*, 5 kD, 10 kD, 30 kD, 50 kD, 100 kD, 300 kD, 0.1 µm±, 0.2 µm±, 0.45 µm±, 0.65 µm± | |

| Holder | TangenX / Pall / Millipore / GE / Sartorius | Universal |

| Membrane Area | 0.01, 0.02, 0.10 m2 | 0.5, 1.5, 2.5 m2 |

| Channel type | L, E, J | |

| *ProStream membrane only ±HyStream membrane only | ||

- Neutral charge

- Low protein binding

- Excellent chemical resistance

- Hydrophilic

- Low protein binding

- Minimal fouling with hydrophobic species

- L Screen (low viscosity)

- E Screen (high viscosity)

- J Open Channel

FLEXIBLE

FLEXIBLE

Multiple channel configurations

Turbulence at the membrane surface minimizes fouling. The result is an increase in performance with a higher permeate flux. SIUS® Cassettes are offered in three different channel configurations to best suit the application. The channel configuration refers to the type of turbulence promoter incorporated into the feed channel of a cassette.

A medium channel or L-screen is offered in all TangenX SIUS cassette formats. The screen creates turbulence at the membrane's surface ensuring outstanding permeate flux with minimal fouling. This channel configuration requires the lowest pumping rate and yields the highest cross flow velocity. This type of channel is best suited for clarified feed streams over a wide range of viscosities.

A coarse screen, the E-screen is offered in all TangenX SIUS cassettes. The screen geometry of this single-use cassette can process feed streams with a higher viscosity and reduce the overall pressure drop. It is scalable from 100 cm2 to 2.5 m2, packaged, sanitized and compatible with existing cassette holders and FPIs. This type of channel is best suited for processes with viscous, high concentration feed streams.

An open channel or J channel is offered in all TangenX SIUS cassettes. A 0.5 mm flow spacer separating the membrane creates an open feed flow channel. This type of channel creates the least amount of turbulence while still minimizing fouling. It also requires the highest pumping rate to pass particulates. This type of channel is best suited for unclarified feed streams and is used for processes such as cell harvest operation.

Selection of TFF Cassette Feed Screen for Efficient Energy Consumption

Download this white paper to learn how different feed channel geometries influence hydrodynamic flow characteristics and their impact on efficient energy consumption.

FLEXIBLE

FLEXIBLE

Compatible with most cassette holders

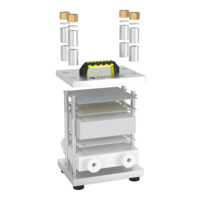

To ensure fit with cassette holders from other manufacturers, SIUS® PD TFF Cassettes for process development are offered with two different notch patterns at the end of the cassette.

TangenX® SIUS® PD with standard notch

0.850in (21.59mm) Offset

This format fits the following cassette holders:

- TangenX® SIUS® PD Cassette Clamps

- Pall Centramate Cassette Holders

TangenX® SIUS® PD with offset notch

0.756in (19.21mm) Offset

This cassette format is compatible wiht holders from:

- Merck Millipore

- Sartorius

SCALABLE

SCALABLE

Scalable from process development to commercial scale

Scalable from process development to commercial manufacturing volumes.

Single-use TFF provides the greatest benefit for small to moderate scale operations.

Reusable TFF is optimal for large production scale operations.

Interested in simulating a cost model for your specific application?

TFF genius

You’re not asking for too much. Combine high selectivity and reduced processing time. Become a TFF genius and get it all with TangenX® Membranes and TFF Devices.

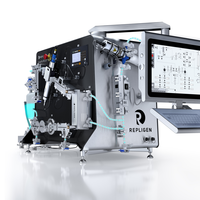

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

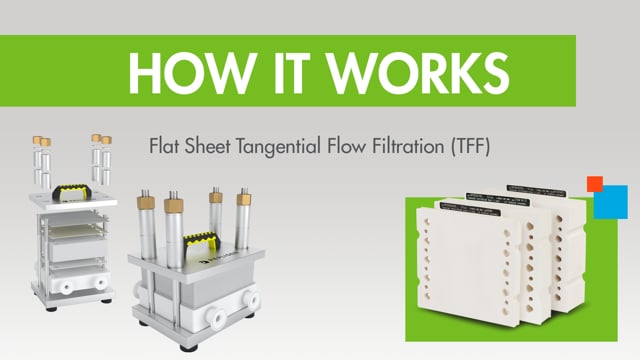

Validated manufacturing

Quality Manufacturing

TangenX® Cassettes are manufactured in a fully validated and documented manufacturing process according to the principles of cGMP. Each cassette comes with a Quality Assurance Certificate.

Comprehensive Regulatory Support Files

Each TangenX® TFF Cassette is supported by a Regulatory Support File (available upon request) that includes:

- Product information

- Cassette design

- Materials of construction

- Product performance

- Safety information

- Documentation system

- Product Manufacturing

- Qualification

- Manufacturing Process Validation

- Release Testing

SINGLE-USE EFFICIENCY

SINGLE-USE EFFICIENCY

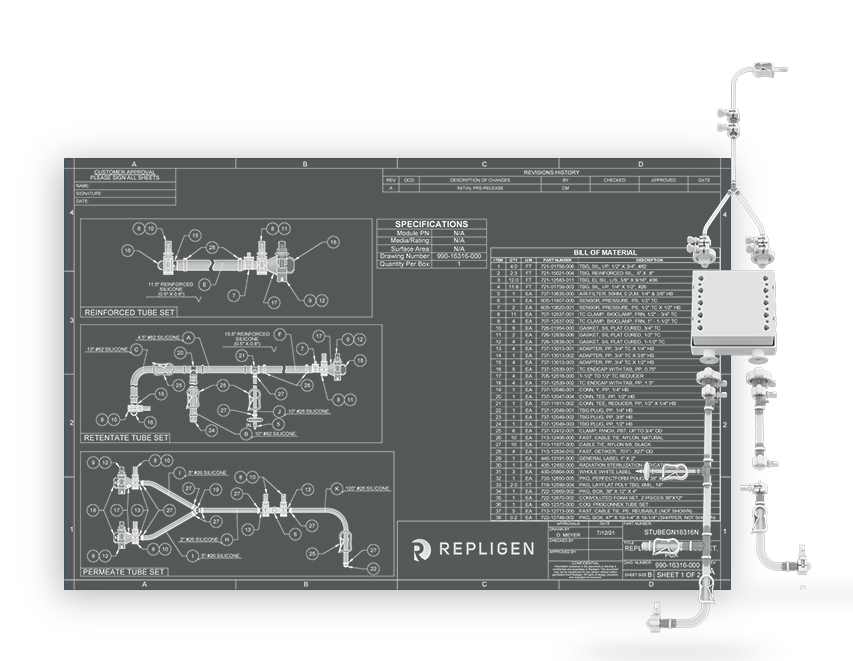

Simple connectivity with ProConnex® Flow Paths

Custom ProConnex® Flow Paths complete your TFF solution. Flow paths are built using Class VI bioprocess-grade materials that are BSE/TSE-free and lot-traceable.

SIUS® Hardware

TSLDI-2BMC (Clamp)

TFPLS-SA08 (Filter Plate)

TSPDI-4BMC (Clamp)

TFP75-SE16 (Filter Plate)

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers