Innovative Upstream Solutions That Power Process Intensification

Smarter technologies for scalable, high-performance bioprocessing

In upstream bioprocessing, every decision impacts yield, quality, and cost. Repligen delivers innovative tools and technologies that help you intensify cell culture processes, streamline development, and scale efficiently from research to manufacturing. Our process intensification solutions address every critical stage of the process from cell culture and real-time analytics to fluid handling and media optimization to empower biomanufacturers to achieve higher productivity, improved space-time yield, greater process control, and significant cost efficiencies across development and production.

Why Process Intensification in Upstream Bioprocessing Is Needed Now?

Growing demand for biologics and advanced therapies is driving the need for smarter, more efficient manufacturing. While improvements in cell lines, feeds, and media have advanced productivity in traditional fed-batch processes, they have reached their limits. Achieving the next level of efficiency requires a smarter, more innovative transformation in how upstream bioprocesses are designed and controlled.

What is Process Intensification?

Process intensification is a strategy used in upstream cell culture to increase the amount of product a bioreactor generates over time. Upstream process intensification surpasses the limits of traditional fed-batch processing by sustaining longer, stronger cell cultures to deliver higher cell densities, more product, and better product quality. Using continuous bioprocessing, real-time process analytics, single-use technologies, and optimized media supplements, process intensification achieves higher productivity while maintaining facility footprint, improving the overall space-time yield of upstream operations.

Intensified Upstream Solutions

Our approach to upstream process intensification brings together the technologies that drive measurable gains in productivity, consistency, and cost efficiency. Perfusion-based upstream platforms enable continuous operation and steady-state cell culture, increasing space-time yield to reduce cost per gram and overall upstream COGs.

When paired with real-time process analytical technologies (PAT), these systems provide the data and control needed to optimize performance and maintain product quality at every stage. Cell culture supplements and single-use fluid management solutions further support intensified operations enhancing cell growth, streamlining transfers, and reducing contamination risk.

Together, these integrated technologies create scalable, data-driven upstream bioprocessing that helps manufacturers intensify processes, improve efficiency, and achieve high-yield biologics production.

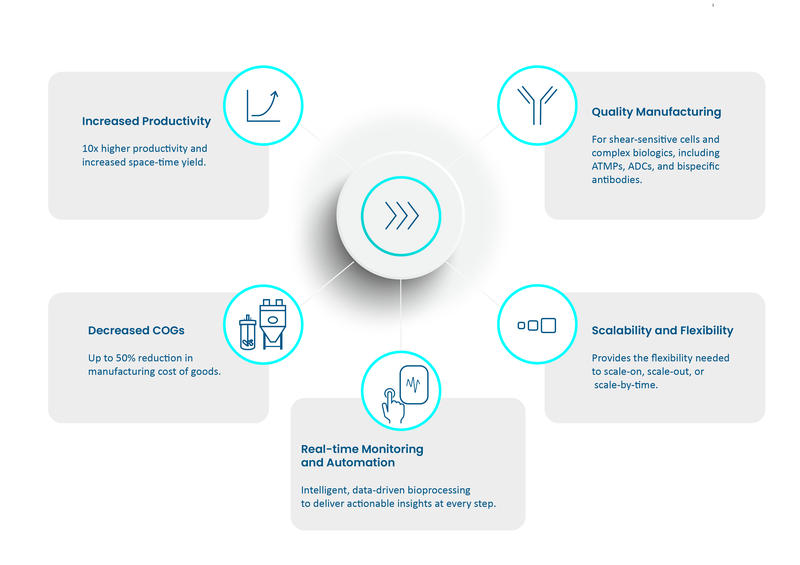

Key benefits that upstream process intensification delivers: Higher productivity, lower cost of goods, better quality, and scalable, real-time controlled bioprocessing.

Driving Upstream Process Intensification with Perfusion Cell Culture

Perfusion cell culture is a continuous bioprocessing method where fresh media is continuously supplied to the bioreactor using a cell retention device while waste and product are simultaneously removed, allowing cells to remain in an optimal growth environment for extended runs. This perfusion intensification approach maintains high cell densities and steady productivity, improving process efficiency and product yield compared to traditional fed-batch methods.

Repligen’s upstream perfusion systems are designed to accelerate process intensification by sustaining high-density cell growth, consistent productivity from process development through commercial scale. Built on decades of innovation, these perfusion systems deliver the performance and reliability needed to drive the transition from traditional fed-batch to fully continuous bioprocessing.

XCell® ATF Systems

At the core of Repligen’s upstream platform, these systems are the industry-standard for higher viable cell densities, increased space-time yield, and reduced cost of goods (COGs) in N-1 seed train intensification and N stage production perfusion.

KrosFlo® KPS TFF System

Built on decades of tangential flow filtration (TFF) expertise, these economical systems combine gentle processing, a wide range of filter selection, and scalable performance within intensified upstream workflows.

KrosFlo® TFDF® System

This hybrid filtration platform marries the benefits of tangential flow (TF) and depth filtration (DF) into a single integrated flow path for continuous clarification and harvest, resulting in higher productivity for viral vector manufacturing, gene therapy, and large molecule filtration.

Smarter, Data-Driven Control of Upstream Bioprocesses

In upstream bioprocessing, the biggest challenge in analytics is the lag between data and decision. Off-line assays can take hours or even days to return results, meaning process conditions may have already changed before insights are available. Even advanced, in-line tools such as Raman spectroscopy offer real-time monitoring but require extensive model development, calibration, and validation before they can be trusted in manufacturing. Together, these limitations slow process optimization, extend development timelines, and add cost to cell culture and media development.

Repligen is committed to advancing intelligent, data-driven bioprocessing. Our PATsmart™ Process Analytical Technology portfolio delivers actionable insights when and where they are needed most—empowering scientists to monitor, optimize, and maintain control across every critical process step. By integrating real-time and at-line analytical technologies directly into upstream workflows, PATsmart solutions accelerate media development, enhance process efficiency, and drive cost savings across biologics, cell therapy, gene therapy, and fermentation applications.

PATsmart™ REBEL® XT | At-Line Cell Culture Media Analyzer

Unlock amino acid and nutrient profiles in minutes, not weeks. The REBEL XT combines capillary electrophoresis and mass spectrometry in a compact, easy-to-operate system that screens 22 analytes in 15 minutes—no core lab, no queue, no waiting. Upstream process development teams gain rapid feedback on media composition to refine feeding strategies, improve clone selection, and optimize product quality across media screening, spent-media analysis, and scale-up workflows.

PATsmart™ MAVEN® | On-Line Glucose and Lactate Analyzer

Monitor and control glucose and lactate concentrations in real time to keep your cells performing at their best. MAVEN enables automated on-line measurement every 2 minutes with precise biosensor-based technology and integrated PID control for direct feed-pump regulation. Tight nutrient control improves cell growth, increases product yield, and reduces lactate accumulation—enabling smarter, more consistent cell-culture processes from development through GMP manufacturing.

PATsmart™ MAVERICK® | In-Line Multiparameter Raman Analyzer

Gain instant in-line visibility of critical process parameters—glucose, lactate, and total biomass—without the complexities of traditional Raman modeling. Powered by a purpose-built de novo model, MAVERICK is ready in minutes for plug-and-play integration with existing automation systems. It supports continuous monitoring of up to six bioreactors simultaneously, enabling closed-loop control, remote access, and seamless scalability from process development to manufacturing.

PATsmart™ Solutions: The Smarter Way to Bioprocess

Actionable data when and where it matters most—supporting smarter, faster upstream decisions on your timetable.

.png) |

|

|

|

|---|---|---|---|

| Application |

REBEL XT |

MAVEN |

MAVERICK |

| Parameter | Amino Acids/Nutrients | Glucose/Lactate | Glucose/Lactate/Biomass |

| Sampling Type | At-line | On-line | In-line |

| Cycle time | ≤ 15 min | Every 2 minutes | Continuous |

| Primary Benefit | Rapid media composition insight | Tight nutrient control | Closed-loop process control |

| Role in Workflow | Media optimization/Feed strategy development | Automated feed regulation/Process consistency | Real-time optimization/Scalability |

Single-Use Fluid Management Solutions for Upstream Workflows

Fluid management in upstream bioprocessing refers to the preparation, storage, mixing, and sterile transfer of media, buffers, and other critical process fluids throughout the cell culture workflow. Reliable fluid management ensures that materials move safely and consistently between steps, maintaining sterility and closed handling as processes scale. As upstream operations intensify and run more continuously, dependable single-use mixing, transfer, and collection systems become essential to reducing contamination risk, streamlining workflow complexity, and keeping high-value cultures supplied and performing at their best.

ProConnex® MixOne RG-X Single-use Mixer

Designed for versatility throughout the bioproduction workflow, the ProConnex® MixOne RG-X offers superior mixing with the patented performance of Zero Gravity mixing technology, and ensures an outstanding user experience and scalability in all aspects.

ProConnex® 2D and 3D Single-use Bags

State-of-the-art flexible and rigid single-use containment solutions engineered specifically for bioprocessing applications. Optimize handling and transfer of high-value liquids with our range of bottles, carboys, 2D bags, and 3D bags.

ProConnex® Singe-use Consumables

From connectors and clamps to single-use transfer lines, and valves, ProConnex® single-use consumables establish reliable, closed fluid paths across upstream operations. These components streamline fluid handling, minimize manual interventions and maintain sterility while supporting intensified workflows.

The ProConnex® portfolio is built on fully in-house extrusion, molding, and assembly capabilities, ensuring tight control over materials, performance, and quality. With extensive customization available, from tubing dimensions and bag formats to connector configurations, our single-use systems integrate seamlessly into any upstream workflow.

Cell Culture Supplements for Intensified Performance

Media optimization is essential for maximizing cell growth, viability, and productivity in upstream processes. Incorporating growth factors such as LONG® R3 IGF and LONG® EGF enhances cell proliferation and metabolic activity, supporting higher viable cell densities for a variety of cell lines used intensified and perfusion cultures. These supplements play a key role in sustaining long-term culture performance, improving consistency, and enabling scalable, high yield biomanufacturing.

LONG® R3 IGF-I

200× more potent and 2× more stable than insulin; LONG® R3 IGF-I is a recombinant analog of human IGF-I engineered to boost cell growth, viability, and culture longevity while supporting higher cell density and productivity.

LONG® EGF

LONG® EGF is a recombinant analog of human epidermal growth factor (EGF) used in therapeutic cell culture applications. It enhances cell proliferation, viability, and productivity, with proven synergy alongside LONG® R3 IGF-I in multiple cell lines.

Fill out this form to be connected with a process intensification expert.