Gene Therapy Process Analytics

With complex transfection workflows and costly materials, gene therapy demands precision—especially upstream. REBEL® provides fast, at-line media analysis to track nutrients, metabolites, and byproducts in real time. Gain insight into media performance, optimize conditions in real-time, and keep development on track without waiting on offline labs. More control, fewer delays, and greater confidence at every step.

Understanding Gene Therapy Manufacturing Complexities

Viral Vectors in Gene Therapy Manufacturing

Gene therapy is a rapidly developing class of biotherapeutics used to replace, insert, or delete genetic material in patients’ cells to treat or cure previously untreatable diseases, such as inherited retinal disease, spinal muscular atrophy (SMA), and sickle cell anemia. While there are several methods of delivering genetic material to cells, the use of viral vectors as the delivery system in vivo is the most widely adopted in the industry. The choice of the vector depends on the efficiency of transgene expression, ease of production, and safety. Common viruses used include Adeno Virus (AV), Adeno-Associated Virus (AAV), Lentivirus (LV), and Retrovirus (RV).

Generation of Genetic Material

Manufacturing of viral vectors is a complex process involving several steps. Typically, it begins with the generation of genetic material to be used for producing the viral vectors. The material used depends on vector type and may include plasmids and helper transducing viruses. Plasmids (pDNA) are manufactured via fermentation of genetically engineered bacteria, such as the Escherichia coli (E. coli). While this process is generally straightforward, without proper optimization, the plasmid DNA yield, topology, and stability may not be suitable for efficient commercial-scale GMP manufacturing. Microbial cultures require specialized growth medium as well as careful monitoring and control of critical process parameters (CPPs) during fermentation.

Host Cell Transfection and Vector Generation

The next step involves production of the viral vector in host cells using one of three methods: stable packaging cell lines, helper virus infection, or transient transfection. Although insect cells, such as Sf9 and other cell types, are sometimes used in production of viral vectors, Human Embryonic Kidney 293 (HEK293) cell lines are the most used to produce viral vectors. HEK293 cells have high transfection efficiency, can produce a variety of different viral vectors (Adeno-associated viruses and Lentiviruses for example) and can be adapted to suspension culture in serum-free medium. This achieves high cell densities and provides suitable glycosylation patterns for efficient virus replication.

There are several challenges related to upstream viral vector manufacturing process (host cell expansion, transfection, and viral vector generation) that need to be addressed to reduce cost, improve safety and efficacy of viral vector-based gene therapies:

- Adapting cells from adherent to suspension culturing and process scale up

- Maintaining high cell density and cell viability while minimizing aggregation during cell culture

- Optimizing transfection protocols to achieve high transfection efficiency

- Achieving high viral titer

- Obtain high ratio of full vs empty viral vector capsids

Optimizing viral vector production is complicated by the changes in metabolic requirements of host cells over the course of the cell culture, for example after cells are transfected. Furthermore, viral replication induces significant changes in the physiology and metabolic state of cells, impacting virus synthesis, assembly, and release. Understanding and modulating cellular metabolism through media development and dynamic control of cell culture parameters can help manufacturers increase viral vector titer, improve capsid quality and potency of gene therapies.

Learn What Nutrients Cells Need for Optimal Expansion & Viral Vector Production

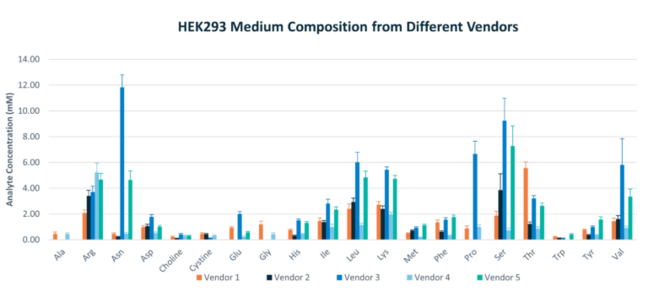

PATsmart™ REBEL® XT provides a tool to support medium screening and optimization. HEK293 media from five different vendors show high diversity in nutrient composition. When starting your development work, do you know if you are screening a diverse panel, and how do you know if these media contain critical components for your process? For example, in a study by Nadeau et al. the role of asparagine (Asn) was noted as crucial for adenovirus virion formation in HEK2931. In the panel of media tested here Asn varies considerably between the five media analyzed with REBEL XT.

With REBEL XT, you will gain actionable insights into composition of media in the panel – and that can explain a lot of the outcome.

Accelerate Media and Feed Development for Faster Time to Market

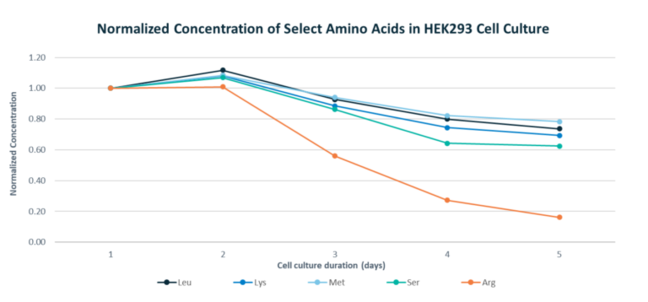

Developing the optimal media formulation and feeding strategy necessitates frequent monitoring of key nutrients’ concentration through the cell expansion, transfection and viral vector production.

Waiting weeks for cell culture media analysis results is not feasible. REBEL XT provides a solution with its rapid analysis turnaround time, small sample volumes, and minimal sample prep.

Screen and Optimize Your Cell Culture Media At-Line

Cell Culture Media Impact on Viral Vector Quality & Safety

Viral vector quality requires serum-free production using more defined, animal-free and/or chemically-defined medium.

Viral Vector Manufacturing & Cell Culture Media Analysis

Efficient viral vector manufacturing for AAV production and lentivirus production is a key element for gene therapy manufacturing.

Plasmid DNA Productivity & Cell Culture Media Analysis

As more cell and gene therapies advance to FDA approval, it is essential to scale up current production processes to increase plasmid DNA productivity.

Cell Culture Media Impact on Viral Vector Production Scalability

To meet market demands in gene therapies, improvements must be made to viral vector production scale-up.

Ensure Process Robustness with Real-Time Monitoring

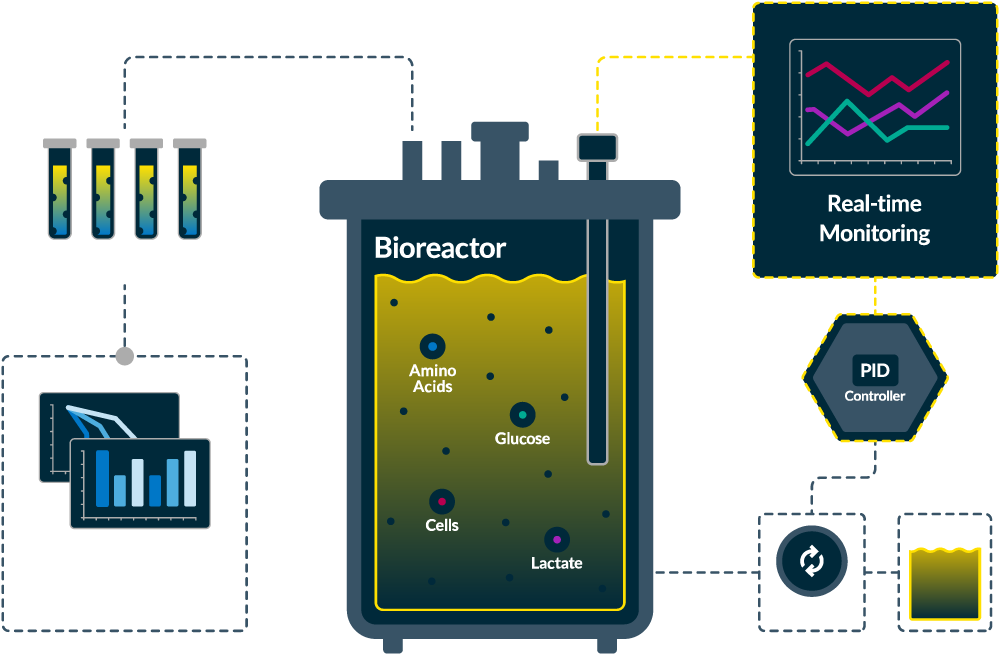

Real-time monitoring and control of physicochemical variables such as pH, dissolved oxygen, and temperature is well established in cell culture processes but is not sufficient for developing and maintaining an optimized viral vector manufacturing process. Regardless of the bioreactor type or the mode of operation (fed-batch or perfusion), continuous monitoring and real-time process control can help achieve several important objectives in gene therapy manufacturing such as increasing viable cell density, improving viral titer, optimizing transfection, reducing media usage, and reducing toxic by-products.

Real-time monitoring of critical process parameters (CPPs) during cell expansion, transfection and viral vector production enhance process understanding, support development of more robust process models, and enable development and implementation of optimized substrate feeding and media exchange strategies.

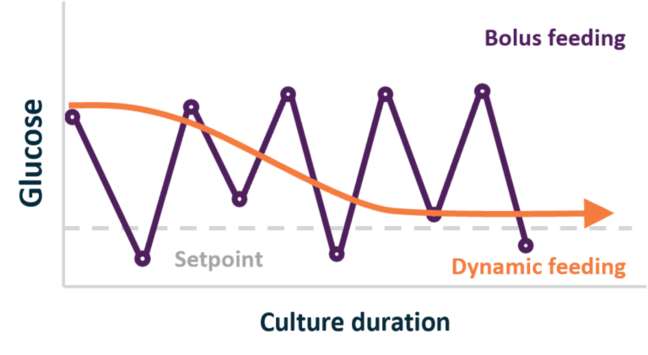

Glucose, being the primary energy source for cells, must be maintained at optimal concentration throughout cell culture duration to provide necessary nutrients and avoid cell stress. Cells’ nutrient requirements do not stay constant through the phases of culture and viral vector production. Nutrient requirements vary with the phase of cell growth, affected by transfection and viral vector generation. Without tight glucose control, enabled by continuous monitoring, glucose levels will fluctuate and destabilize cellular metabolism leading to cell stress and negative effect on viral vector production. Suboptimal glucose levels may lead to variations in vector characteristics such as infectivity, transgene expression levels, and vector stability. Tight control over glucose concentration allows for consistent production of high-quality viral vectors with reproducible properties. Real-time monitoring of glucose helps implement dynamic control of feeding and media exchange which can significantly reduce media and feed usage by as much as 60% without affecting productivity2.

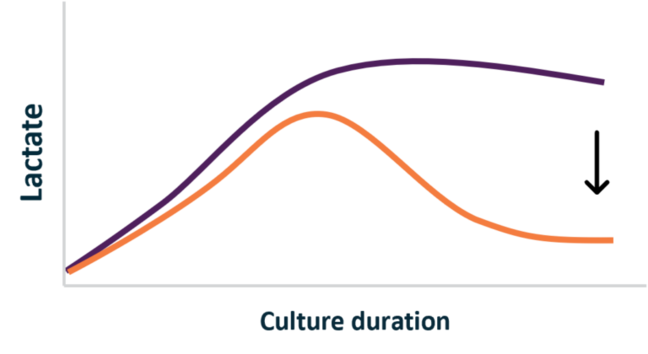

In addition to glucose, lactate is another critical parameter that needs to be continuously monitored. Lactate accumulation can indicate metabolic stress in the cells, which can compromise their ability to produce viral vectors. Additionally, lactate accumulation can lead to decrease of media pH and negatively affect cell growth, viability, as well as the stability of viral vectors produced.

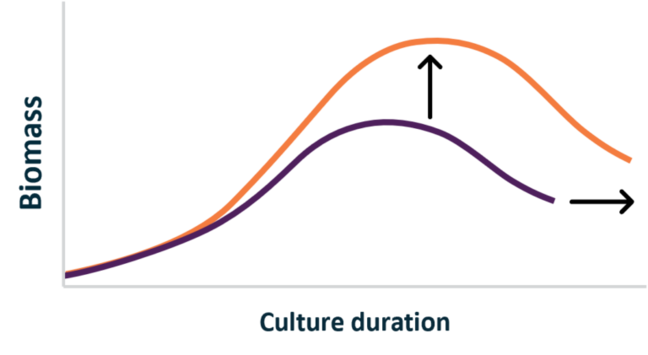

Real-time total biomass measurements, correlated to the total cells counts, is vital for ensuring consistency and efficiency of viral vector manufacturing. Total biomass information can help identify deviations from the expected cell growth trajectories and maintain process parameters within the specified operating ranges. Transfection efficiency, the proportion of cells that successfully uptake the plasmid DNA, is influenced by cell density hence, real-time total cell count information can be used to optimize transfection protocols.

The success of the triple transfection process relies on optimizing key parameters of cell culture and refining the feeding strategy. Critical parameters, such as glucose and lactate, impact cell viability, transfection efficiency, viral vector titer and quality, hence, must be meticulously monitored and controlled during the cell culture process.

[2] Valkama AJ, Leinonen HM, Lipponen EM, Turkki V, Malinen J, Heikura T, Ylä-Herttuala S, Lesch HP. Optimization of lentiviral vector production for scale-up in fixed-bed bioreactor. Gene Therapy. 2018 Jan;25

At-line Monitoring of Amino Acids

At-line Monitoring of Amino Acids

Amino acids are critical to cellular function and viability, but different cells may consume them at different rates. Monitoring concentrations of amino acids during cell expansion helps prevent their depletion that may cause a batch failure.

Real-time Glucose Monitoring

Real-time Glucose Monitoring

Glucose is the primary energy source and its concentration in the media regulates metabolic pathways and is linked to proliferation, metabolites production, and phenotype expression. Continuous glucose measurement can be used for control of substrate feeding or media exchange pumps.

Continuous Lactate Monitoring

Continuous Lactate Monitoring

Excessive accumulation of lactate can inhibit cell growth and decrease cytokine secretion. It can also be used to estimate cell count, predict cell expansion rate, determine optimal harvest time.

In-line Biomass Measurement

In-line Biomass Measurement

In-situ Total Cell Density (TCD) measurement can be used to ensure that appropriate cell densities are achieved, especially in adherent cell cultures where cell counting is difficult to perform.

Your Choice for Ultimate Monitoring and Control of Viral Vector Production

Our suite of devices provides the data you need, where and when you need it.

Implement Process Analytical Technology (PAT) in Your Cell Therapy Workflows

Historically, automated cell therapy manufacturing systems had limited real-time monitoring capabilities due to lack of robust and compatible process analytical technologies. PATsmart™ MAVEN® and PATsmart™ MAVERICK® are offered with a variety of single-use and reusable process interfaces and multiple analog and digital communication options making integration possible with a number of manufacturing automation systems.

PATsmart™ REBEL XT® At-line Media Analyzer

At-line Analysis for Cell Culture Media

Built on the proven foundation of the award winning PATsmart™ REBEL® analyzer, the PATsmart™ REBEL XT® System continues to challenge the limits of traditional lab testing—delivering the next level of at-line cell culture media analysis with greater reliability, streamlined usability, and tighter analytical performance. Designed for real-world cell culture media process development, it delivers faster, real-time insights into media composition—giving you the data you need, exactly where and when you need it.

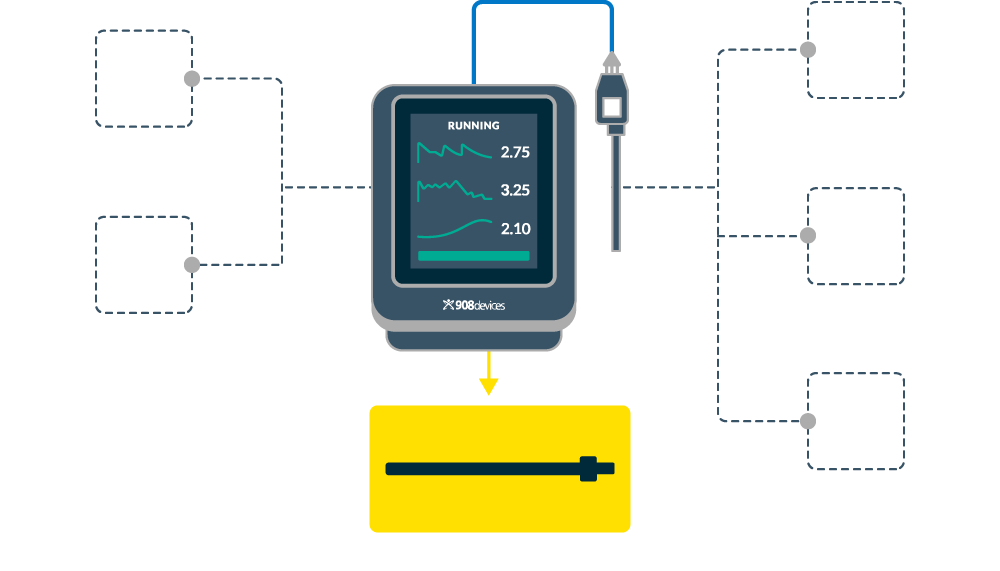

PATsmart™ MAVERICK® In-line Critical Process Parameter Monitoring

Process Analytical Technology for In-line Bioprocess Analysis

This easy-to-use process analytical technology device offers in-line bioprocess analysis and control with no complex modeling. Measure multiple critical parameters across media, across processes, across mammalian cell lines, across scales.

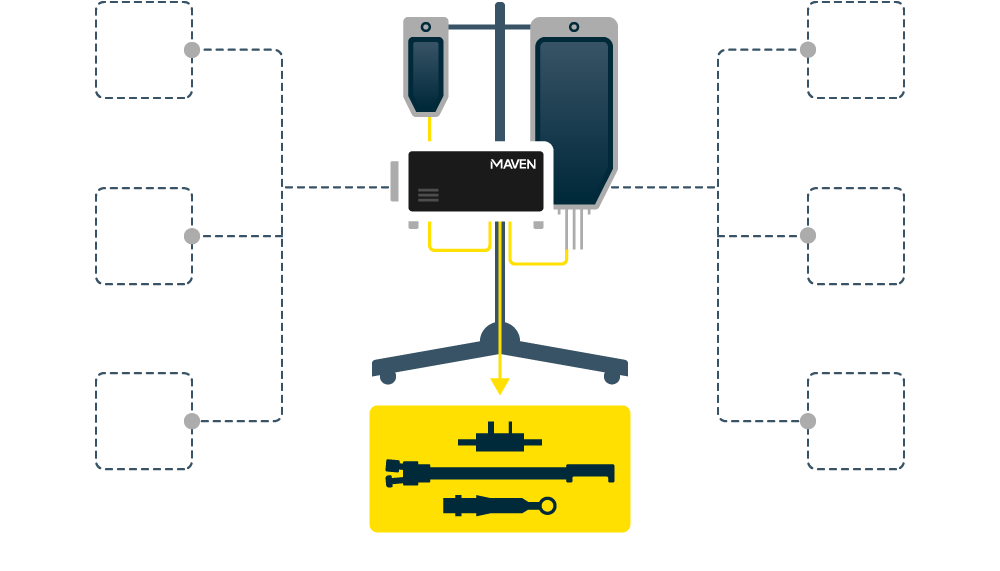

PATsmart™ MAVEN® Online Glucose and Lactate Monitoring

Take command of your cell culture process with the PATsmart™ MAVEN® Online Glucose and Lactate Monitoring System. Delivering continuous, sample-free glucose data every 2 minutes, MAVEN automates feeding strategies, reduces variability, and frees your team from manual sampling. Built to integrate seamlessly, it brings precision and efficiency to every run—without disrupting your workflow.