KRM™ Chromatography Systems

CHROMATOGRAPHY REDESIGNED

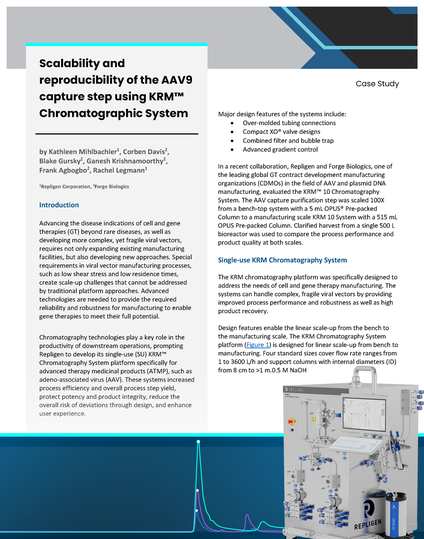

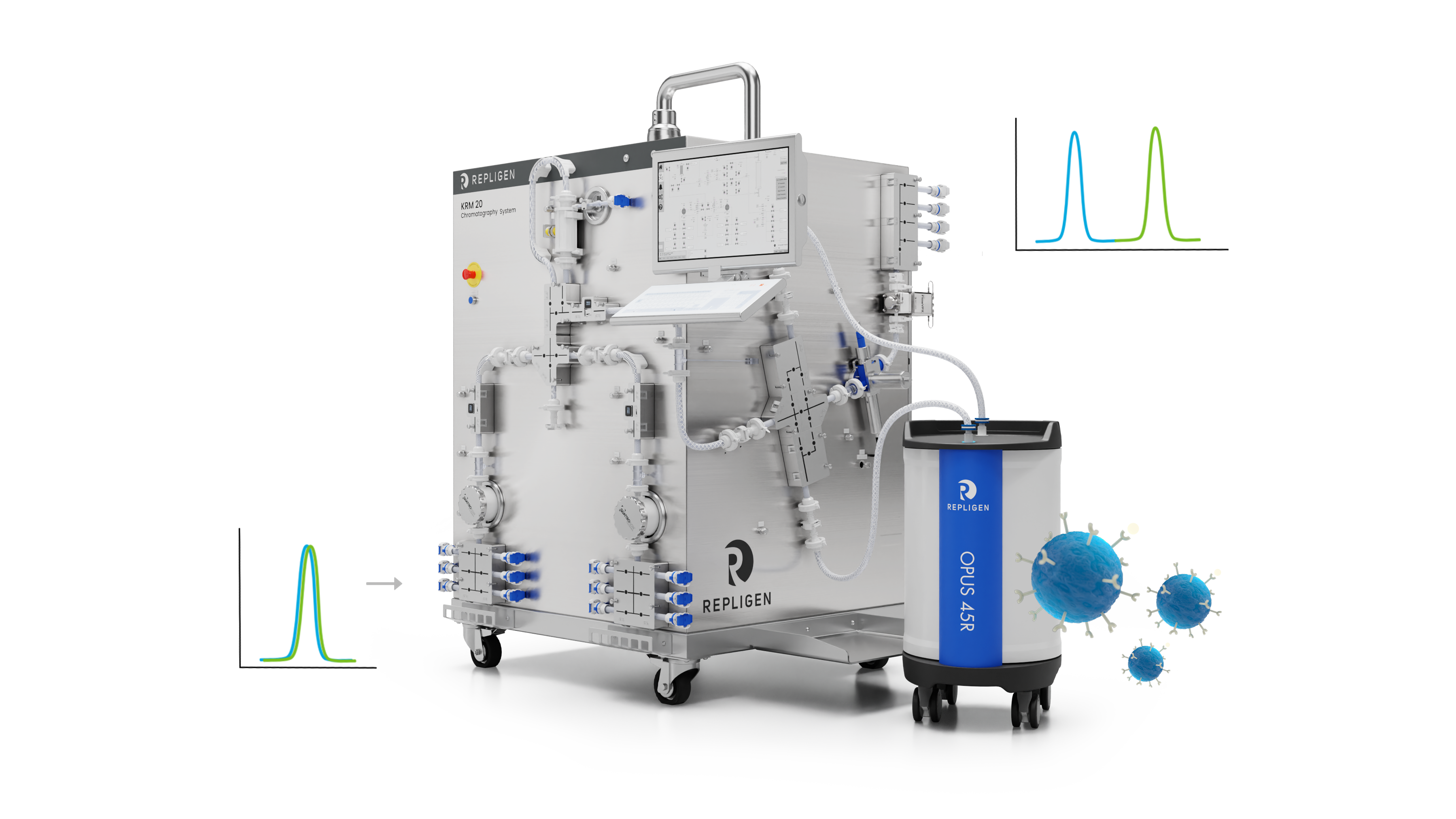

The KRM System embodies decades of transformative technology innovation, resulting in a rapidly scalable single-use platform for unprecedented recovery of complex biomolecules and new modalities.

Every drop counts

Maximize recovery of new modalities

Valve blocks eliminate dead legs

One design scaled perfectly

Scale effortlessly

Innovation and precision engineering at four different sizes

100% Single-use and Simplified

Operator efficiency and risk mitigation

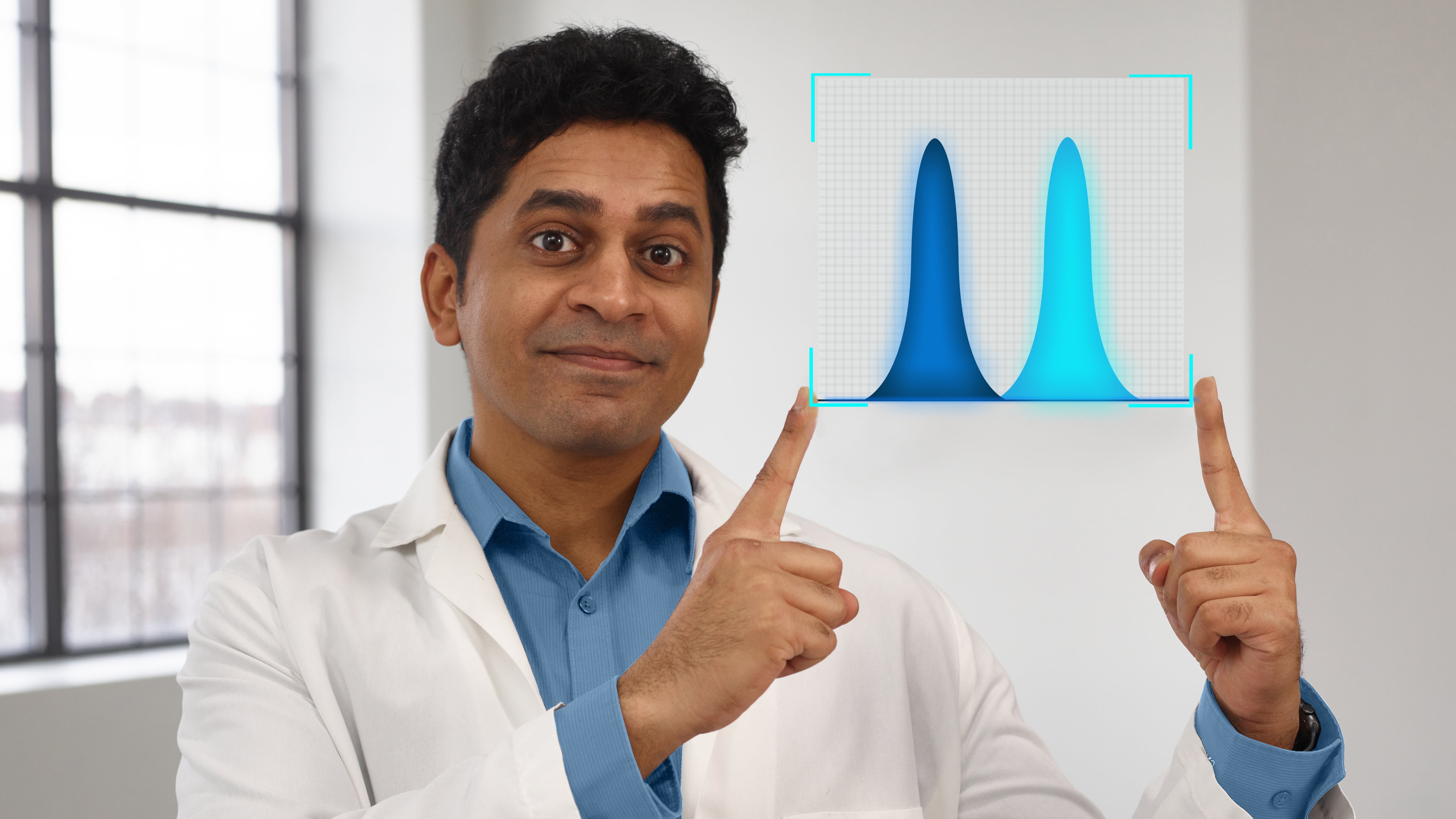

App Note: Scale to 500L with ≥13% recovery increase

Repligen, in collaboration with Forge Biologics conducted a case study where AAV capture purification step was scaled from 1L at PD to 500L at pilot scale. The results demonstrated an overall recovery increase of ≥13% with no increase in impurities.

every drop counts

every drop counts

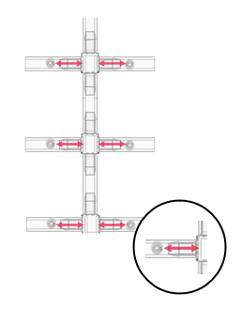

Innovative valve block technology eliminates dead legs

Repligen valve blocks support consistent flow dynamics from mixing valve to column.

Traditional valves

Hose barb connections create dead legs and increase hold-up volume across the flow path.

Zero-dead leg valve block technology

Injection molding and overmolded connections at critical junctions eliminate dead legs and decrease hold-up volume.

EVERY DROP COUNTS

EVERY DROP COUNTS

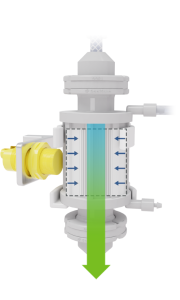

Low hold-up filter and sensor solution replaces bubble trap

Traditional bubble trap

Up to 500 ml of hold-up volume can uncontrollably disrupt gradient, causing back mixing and dilution, harming reproducibility and recovery.

Repligen filter and level sensor solution

- Use of a filter minimizes hold up volume helps maintain gradient control and promotes higher recovery

- A level sensor coupled with the filter enables the automation of air release

EVERY DROP COUNTS

EVERY DROP COUNTS

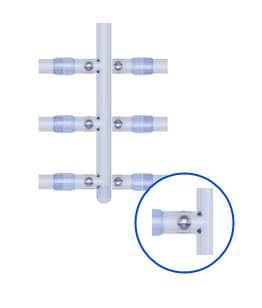

Over-molded connections reduce shear stress

Hose barb connections create dead legs and increase hold-up volume across the flow path.

Traditional technology

Traditional solutions utilize hose barbs, zip ties and individual valves at tubing junctions causing excess shear stress to the product as inner diameter narrows and flow dips into significant dead legs.

Repligen Technology

The consistent ID of overmolded connections coupled with injection molded tubing and valve block hardware at critical junctions eliminate dead-legs, minimize shear stress and protect product integrity.

ONE DESIGN SCALED PERFECTLY

ONE DESIGN SCALED PERFECTLY

Innovation and precision engineering at four different sizes

To remove process scale-up challenges, KRM™ Systems are part of one family built off of one design. The goal is to streamline scale-up from 1 L/h to 3600 L/h.

- One optimized flow path design

- Consistent hardware, including pumps

- Identical user experience

SINGLE-USE AND SIMPLIFIED

SINGLE-USE AND SIMPLIFIED

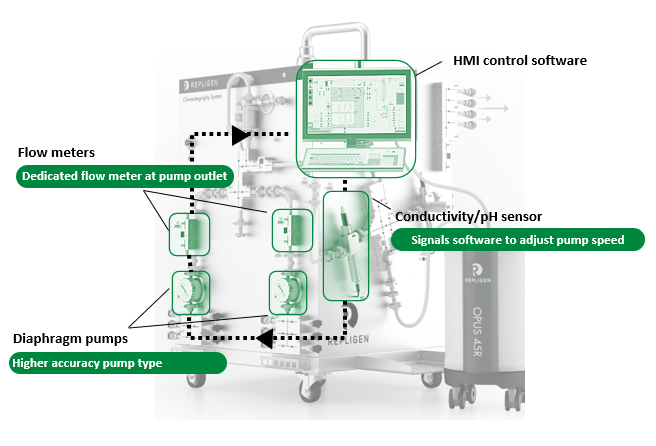

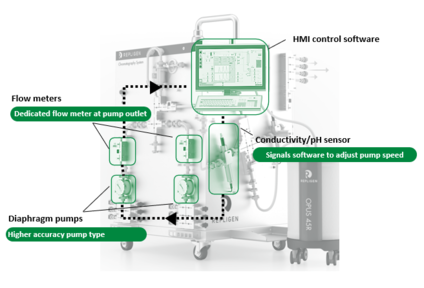

Precise buffer control enables maximal product recovery

Precise process control of buffer composition, optimal flow path and hardware design unlock accurate gradient control and improved recovery.

SINGLE-USE AND SIMPLIFIED

SINGLE-USE AND SIMPLIFIED

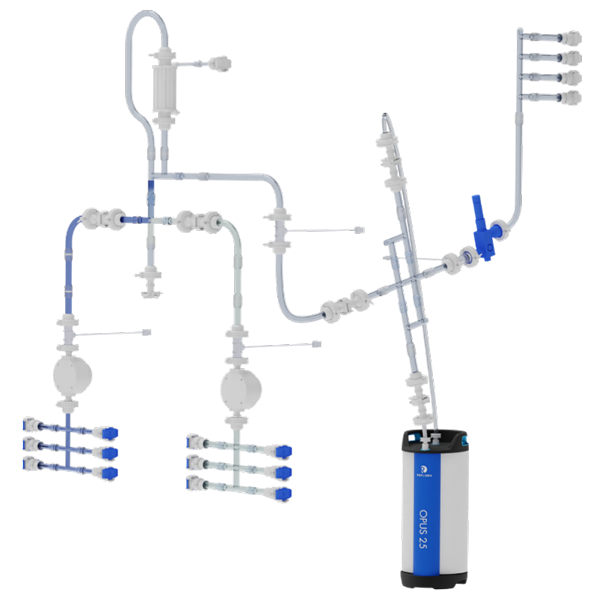

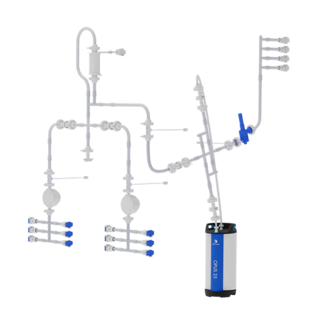

Error-free installation in minutes with pre-assembled flow paths

ProConnex® Flow Paths, pre-assembled and specific to the KRM™ System, are intuitively designed for simple, mistake-free installation. All system sensors are pre-calibrated and assembly is done in minutes with no confusing instructions.

Watch ProConnex® Flow Path installation on the KRM™ 20 Chromatography System.

Compliance and Control

Compliance and Control

Software for modern GMP manufacturing

The KRM Chromatography Systems utilize an intuitive and recipe-driven software platform to power fully automated processes. Pre-built templates and advanced configurability enable you to unlock the full potential of automation and maximize the output of each run.

All operational functions in one user friendly screen increasing operator efficiency and reducing the amount of training required.

Your process outcome is only as good as your recipe. Whether its pre-configured templates or the flexibility to build from scratch- this recipe editor will help you succeed.

Running a fully automated cGMP process has never been easier. From recipe upload to completion, the software is here to make sure you stay on track.

Software/Recipe Editor

- Intuitive point and click interface

- Extensive pre-configured recipe templates and flexibility to create your own

- Sequential flow charts for recipe visualization

- Windows-integrated access control

- Recipes directly transferable between systems

- Recipes can be paused and adjusted during run while maintaining batch integrity

Control hardware

- Allen Bradley industrial PLC

- HMI with a touch-screen and glass keyboard

Secured connectivity

- Ethernet/IP and OPC/OPCUA

- to external Scada/DCS/MES systems

Compliance

- GAMP5 and 21 CFR Part 11

- SA88 standards

- UL/CE

Reporting and trending

- Secure batch reports

- Customizable data trending

- SQL data base

- Historized tags and calculated values

Alarms and events

- Customizable process alarms

- Secured alarm and event logs

Chromatography Redesigned

Repligen is revolutionizing how modern chromatography is performed. The result? Unprecedented recovery and operational efficiencies even with the most complex modalities.

Click on the image highlights to see key elements of chromatography redesigned.

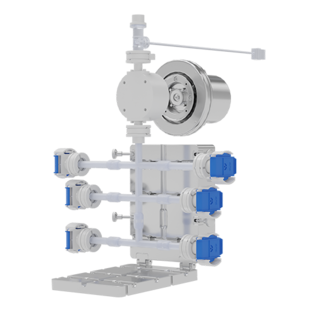

KRM™ Chromatography Systems

Incorporating transformative Repligen innovations in hardware engineering, fluid management and process control, KRM Chromatography Systems are designed to mitigate risk of leaks and contamination and enable an efficient, user-friendly batch change.

Click on the tabs to explore features of the different KRM Chromatography Systems and Flow Paths.

KRM™ 10 Chromatography System

1 – 180 L/h | 1/4“ ID

Click on the links to explore different features.

KRM™ 20 Chromatography System

6 – 900 L/h | 1/2“ ID

Click on the links to explore different features.

KRM™ 30 Chromatography System

25 - 2000 L/h | 3/4“ ID

Click on the links to explore different features.

KRM™ 40 Chromatography System

50 - 3600 L/h | 1“ ID

Click on the links to explore different features.

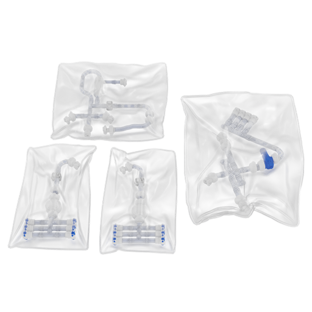

KRM™ Flow Path

Click on the links to explore components of the Flow Path.

1. Receive 4 gamma irradiated flow path sub-assemblies.

2. Assemble and install the flow path

- Pre-calibrated sensors

- 3 connections aseptic/hosebarb

3. Perform chromatogrpahy on the KRM System

No more speed bumps, sudden turns and dead-ends along the flow path. Give your gradient the upgraded ride it deserves and recover more product.

Questionable design prevents you from getting the job done. Experience higher recovery and faster batch changes with simple and expertly crafted chromatography flow paths and hardware.

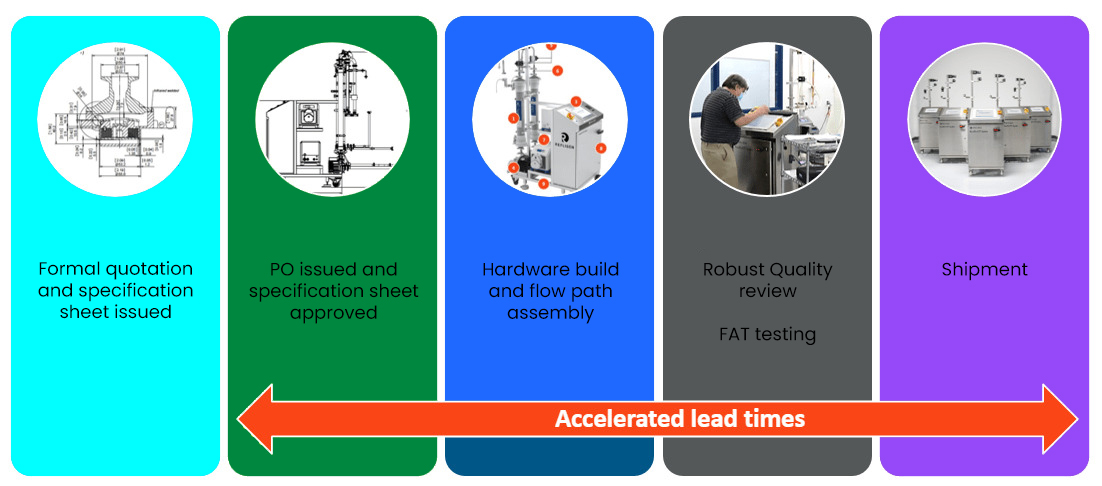

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Expert Project Management

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers