AVIPure® AAV Affinity Resins

AVIPure® AAV and HiPer™ AAV Affinity Resins provide capture step purification of adeno-associated virus (AAV) 2, 8, and 9 vectors, delivering high binding capacity and fast flow rates for rapid capture.

Superior performance

- High dynamic binding capacity

- High target molecule purity and complete elution at pH 3.0

- Innovative macroporous bead technology

Improved process productivity

- Efficient mass transfer for rapid processing

- Only 30-60 seconds residence time

- Supports fast flow rates

Stability and scalability

- Retains over 80% DBC after 10 hours exposure to 0.5 M NaOH

- Designed to scale easily from process development to commercial manufacturing

The Next Generation of Affinity Resin Technology

Introducing AVIPure® HiPer™ AAV resins—the next generation of affinity chromatography resins from Repligen.

AVIPure® HiPer™ AAV resins use an innovative macroporous bead structure, which allows for convective flow both through and around the beads. Unlike traditional resins, this large pore structure maximizes surface area for high dynamic binding capacity while also supporting rapid flow-through and elution.

These large pores are ideal for the purification of large molecule biologics, such as viral vectors, viruses, and nucleic acids.

AVIPure® HiPer™ AAV9 resins and AVIPure® HiPer™ AAV8 resins are currently available using this technology. Additional AAV resins will be made available on the HiPer™ format in the future.

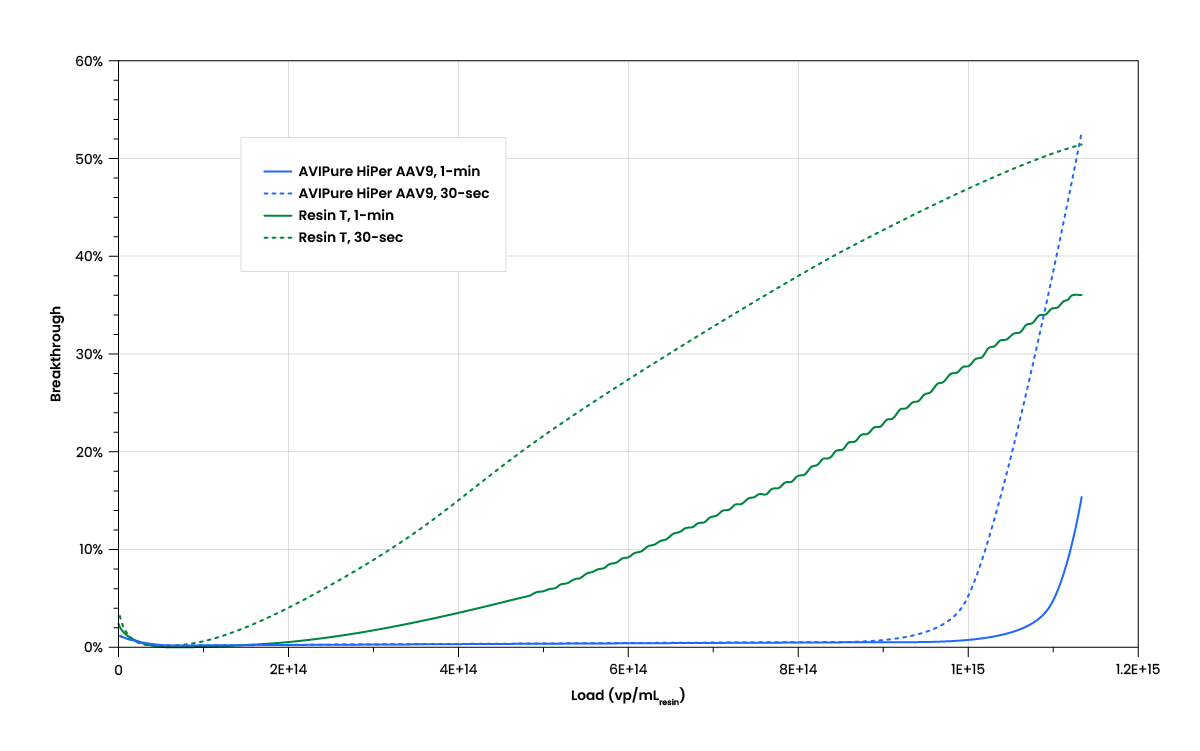

High Performance at Fast Flow Rates

The AVIPure® HiPer™ AAV9 affinity resin consistently delivers higher binding capacity (1.0E+15 at 30 seconds residence time) compared to a leading commercial AAV affinity resin, even at fast flow rates, allowing for faster processing. This resin demonstrates a sharp breakthrough curve, translating to minimal loss of valuable capsid material.

Dynamic binding capacity is expressed as 5% breakthrough.

Dynamic binding capacity of AVIPure® HiPer™ AAV9 resin vs. leading commercial resin, “Resin T,” after 30 seconds residence time and 60 seconds residence time.

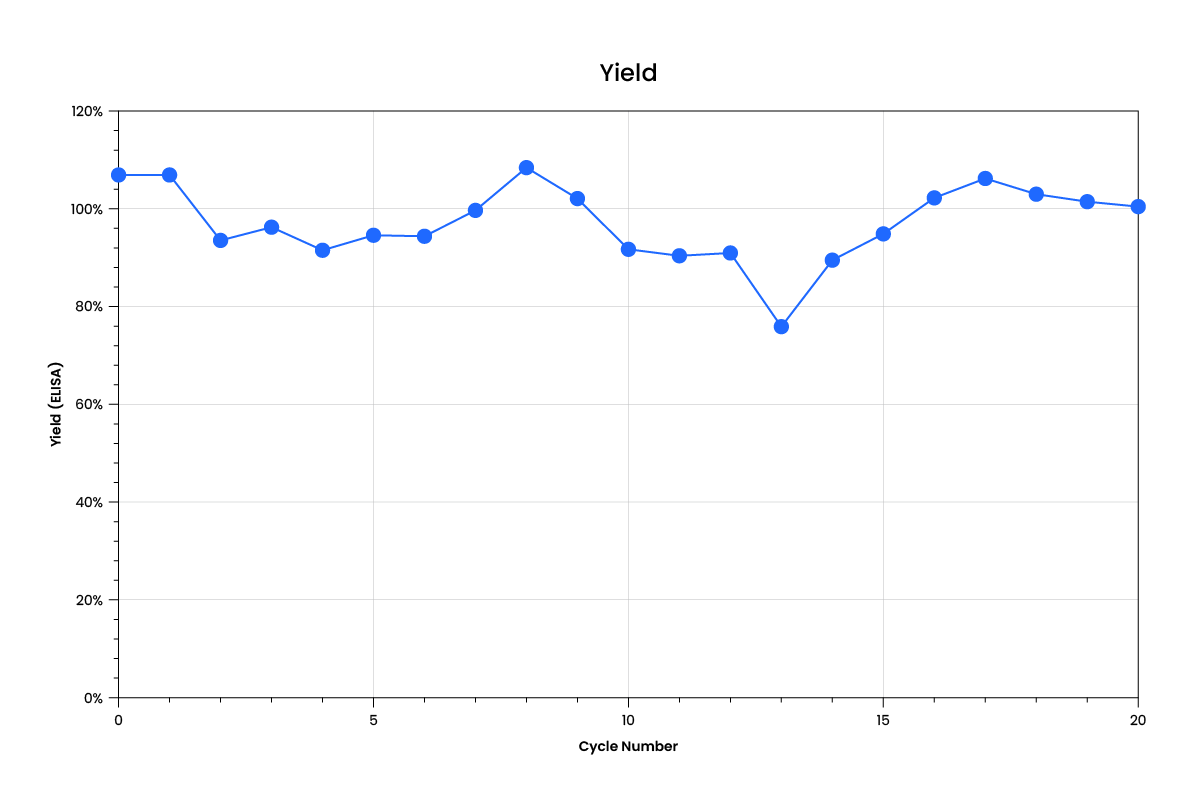

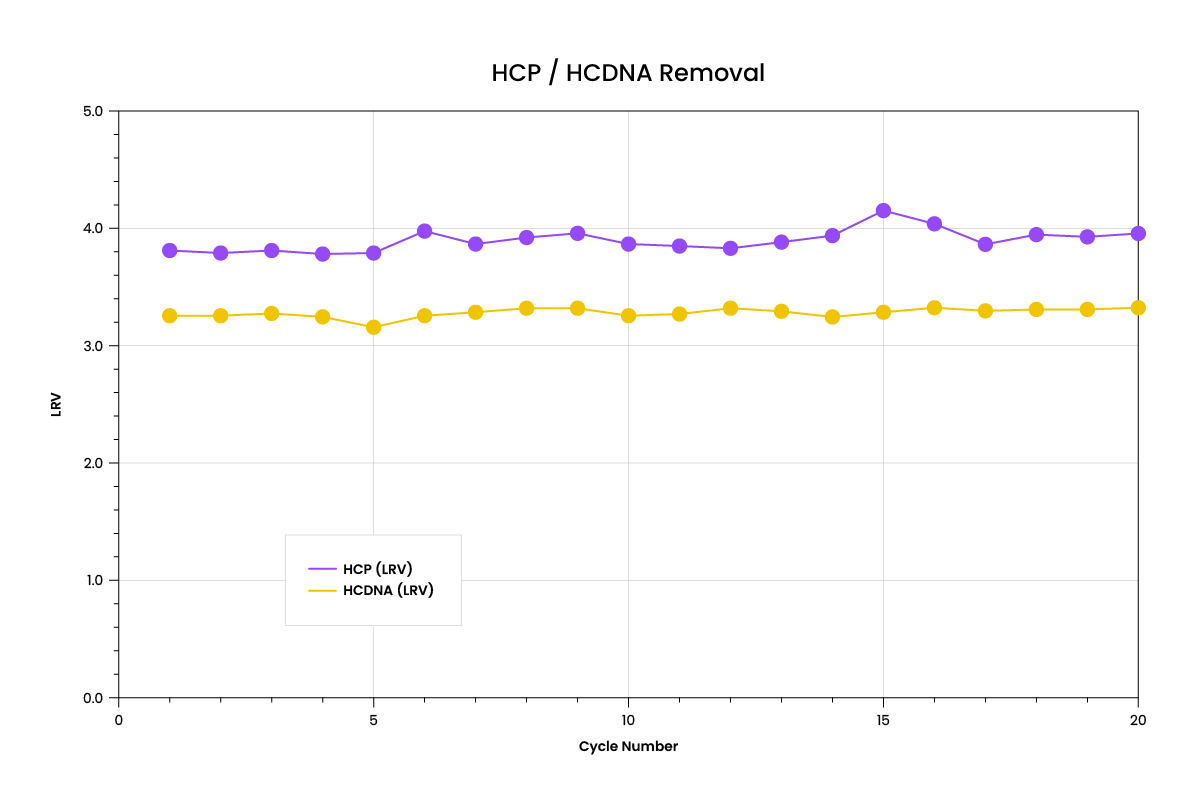

The AVIPure® HiPer™ AAV9 resin delivers robust, reliable performance. Yield, log reduction of host cell protein, and amount of residual ligand remain consistent over 20 product cycles.

Process parameters include:

Titer: Progen AAV9 XPeress ELISA

Yield: Progen AAV9 XPeress ELISA

HCP purity: Cygnus HEK293 HCP ELISA

HCDNA purity: ThermoFisher Quant-iT

HMW aggregates: HP-SEC, Phenomenex Biozen dSEC-7, 700 Å, 3 µm, 150 x 4.6 mm

Residual ligand: Cygnus Avitide AVIPure® – AAV9 Residual Ligand Assay Kit - (F970)

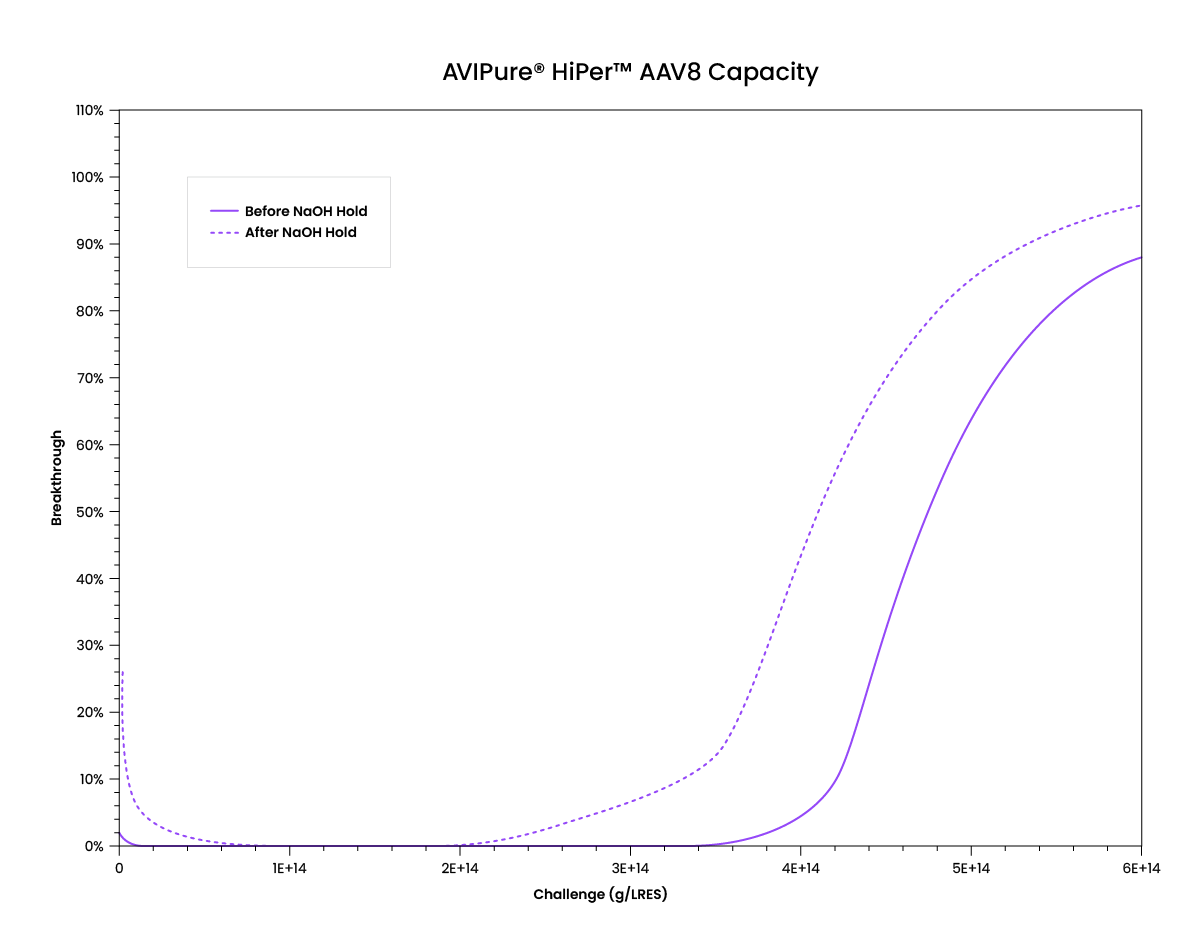

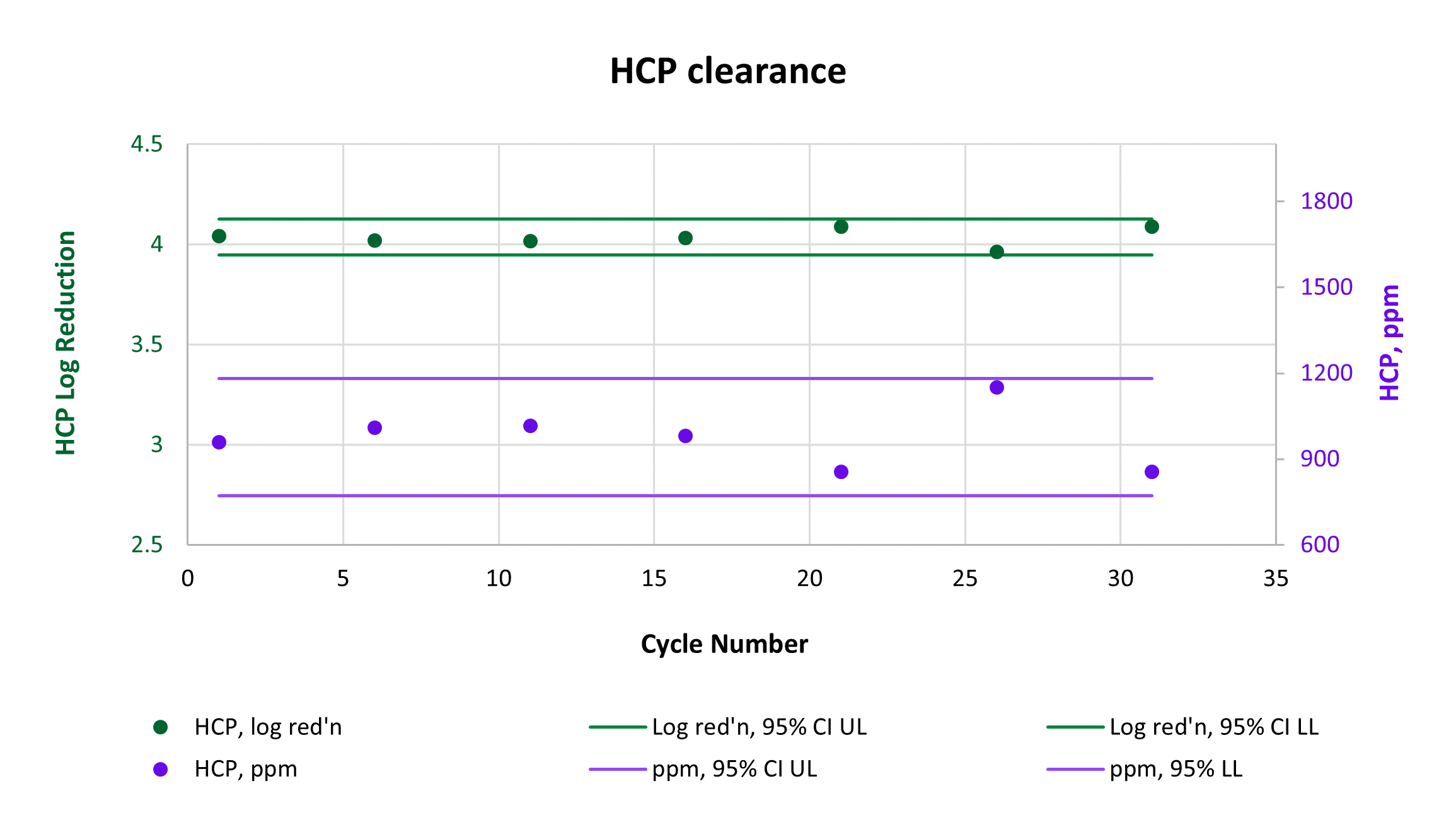

The AVIPure® HiPer™ AAV8 affinity resin maintains high performance through extended clean-in-place (CIP) cycles. It can withstand at least 10 hours of exposure to 0.5 M NaOH, while retaining 80% of the initial dynamic binding capacity.

Dynamic binding capacity of the AVIPure® HiPer™ AAV8 resin before and after 10 hours of exposure to 0.5 M NaOH.

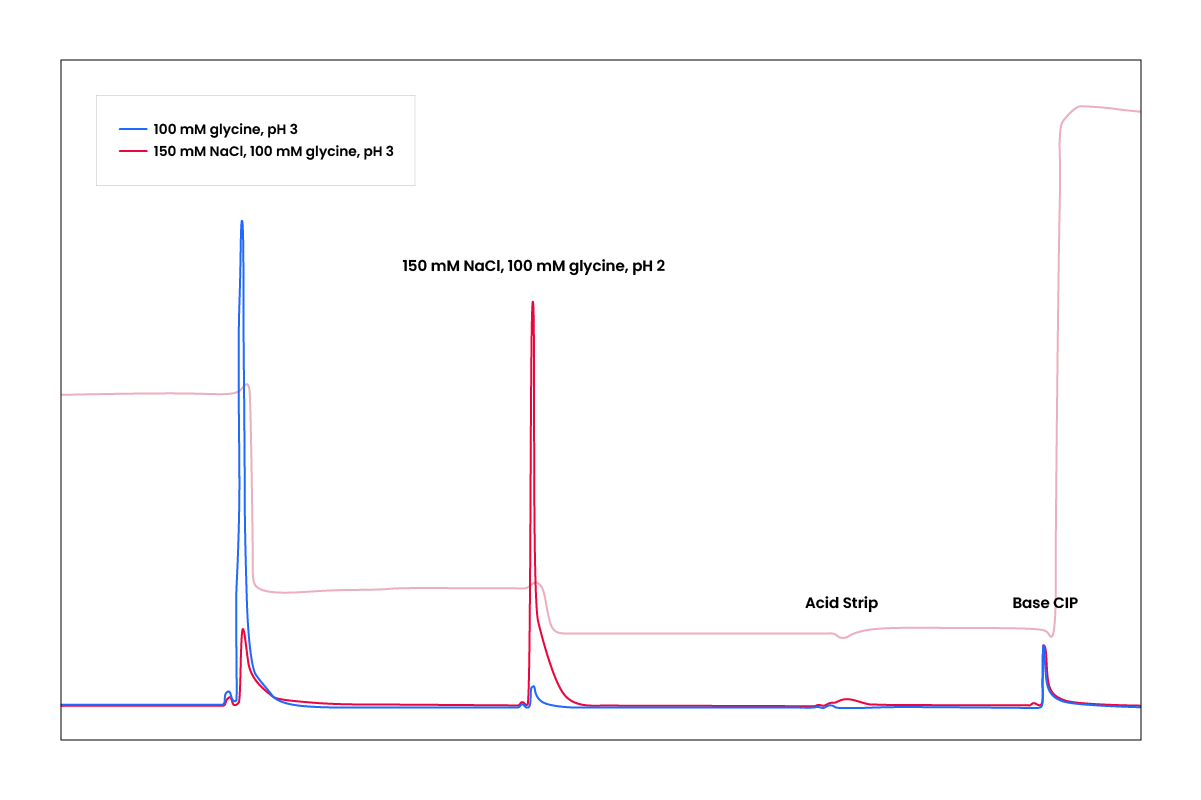

Representing an evolution in AAV8 resin technology compared to previous-generation AVIPure® AAV8 resin, the AVIPure® HiPer™ AAV8 resin achieves complete elution at pH 3 with a low-conductivity buffer and without requiring NaCl. Low-conductivity elution enables less dilution prior to the polish step using anion exchange for empty/full capsid separation.

The AVIPure® HiPer™ AAV8 resin achieves complete elution at pH 3 without NaCl. For processes that require NaCl, the resin also supports elution at pH 2 using 150 mM NaCl.

Designed for Scalability

AVIPure® HiPer™ resins are designed to scale easily from process development to commercial manufacturing. Efficient mass transfer, high target molecule yield, and fast processing support improved process efficiency.

Two-Step Capture and Polish Solution

When paired together, AVIPure® HiPer™ AAV affinity resins and the HiPer™ QA resin form a two-step solution for AAV capture and polish. Unlike other commercial resins, the HiPer™ QA resin is designed specifically for the polish step of AAV manufacturing and achieves separation of empty vs. full capsids containing the target AAV genome. This two-step purification process results in high purity—without sacrificing process efficiency—to support safety and efficacy in gene therapy manufacturing.

HIGH PERFORMance

HIGH PERFORMance

High-performing AAV affinity resins on agarose matrix

The previous generation of AVIPure® AAV 2, 5, 8, and 9 Affinity Resins meet or exceed the performance metrics of resins developed on alternative platforms with the additional benefit of robust alkaline stability. Affinity resins offer the ability to simplify downstream processing. NaOH stable affinity resins simplify processes and dramatically improve overall process economics. These resins remain available to support continuity in GMP manufacturing processes.

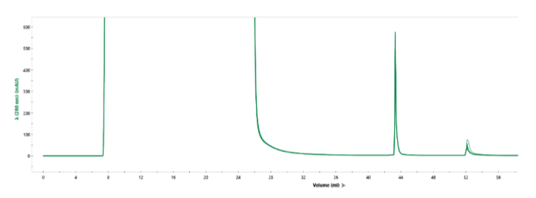

- Maintain high host cell protein (HCP) clearance and residual DNA clearance levels after 20 cycles

- Across life of the resin using 0.1 to 0.5 M NaOH for routine cleaning and sanitization

- High dynamic binding capacity even at short residence time enables use with pre-concentrated feed or direct capture:

- >2 x 1014 vp/mLresin at 1 minute residence time

- >7 x 1014 vp/mLresin at 4 minute residence time

Impact of Low pH Affinity Chromatography Elution on AAV Transduction

Affinity chromatography enables effective AAV purification for gene therapy, but the use of acidic pH (pH 2–3) for elution raises concerns about virus stability. Studies across different pH conditions and temperatures showed minimal impact on infectivity at 25°C, with some aggregation and loss of infectivity for AAV8 at 40°C. Throughout downstream purification, virus aggregation was linked to capsid concentration rather than the capture process, and immediate pH neutralization after elution helps mitigate stability risks.

Retain performance with NaOH CIP regeneration

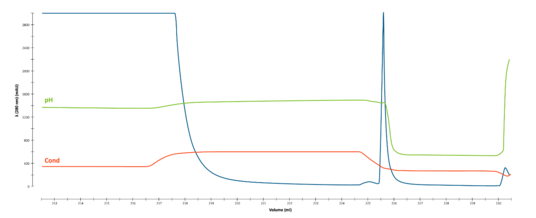

Overlay of every fifth cycle from a single AVIPure® AAV2 column used in a 31-cycle study demonstrating robust chromatographic performance after cleaning in place with NaOH. Total NaOH exposure time at final cycle was 15 hours.

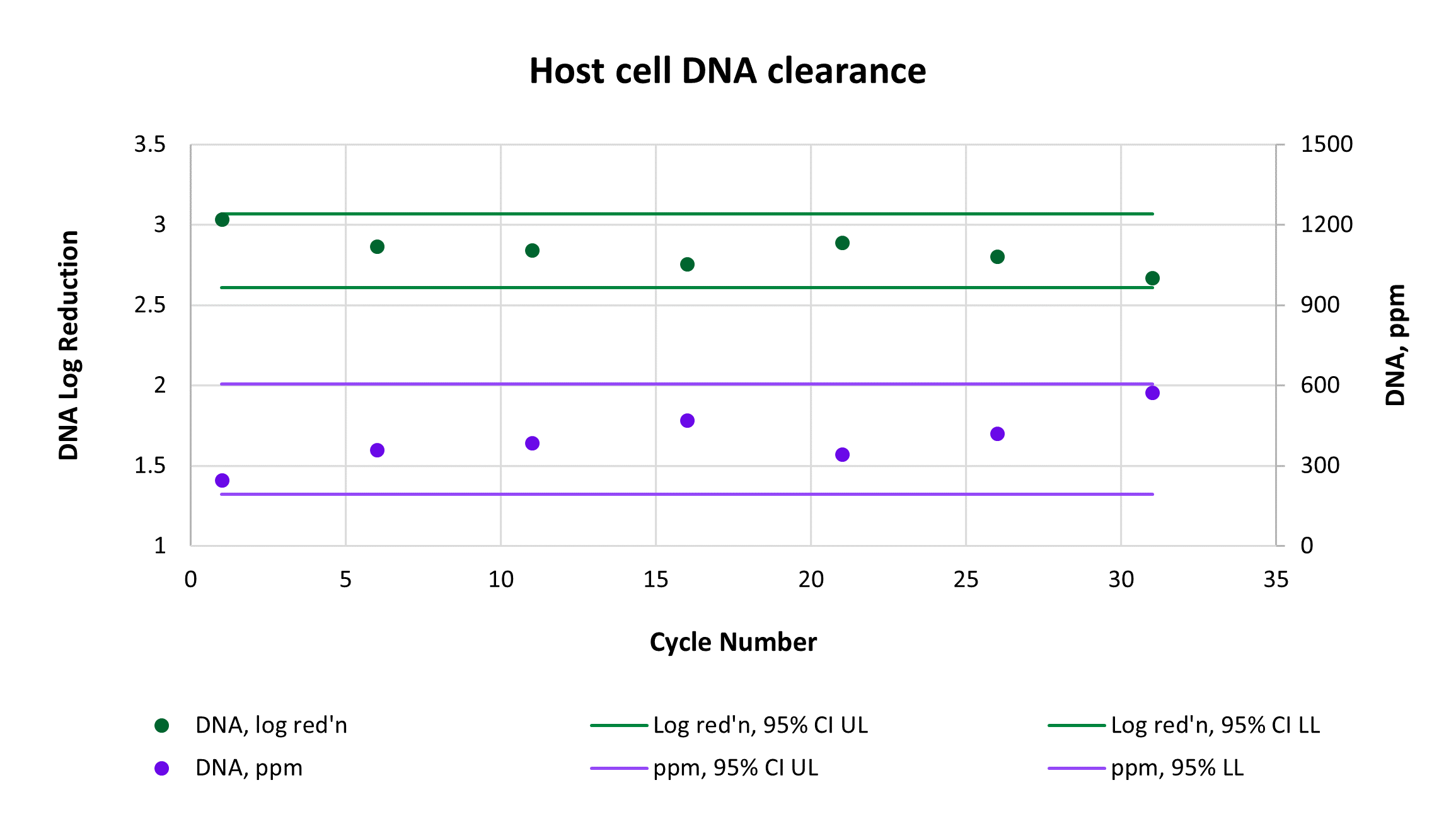

Consistently high yield and clearance of host cell protein (HCP) and host cell DNA (hcDNA) were achieved across 31 cycles on a single AVIPure® AAV2 column. Yield was measured using commercially available AAV2 Progen ELISA kits, HCP was measured by HCP ELISA, and hcDNA was measured by Picogreen assay. Average yield was 105%, average 4.0 log reduction of HCP to 977 ppm, and average 2.8 log reduction of hcDNA to 400 ppm.

Bind with 2-minute residence time, Clear more HCP and DNA

Bind, wash and elute direct capture of AAV cell culture feed (not concentrated) stream using AVIPure® AAV2 Resin.

A 2 -minute residence time enabled elimination of an existing pre-concentration step. Product was eluted in 50 mM glycine, 150 mM NaCl, 0.01% P188, pH 3 with 85% recovery.

AVIPure® AAV2 Resin and a competing AAV affinity resin were run under identical conditions. The eluted product was analyzed for purity by SDS-PAGE, HCP and residual DNA.

AVIPure AAV2 Resin and a competing AAV affinity resin were run under identical conditions (2 minute residence time) with the eluted product analyzed for purity by SDS-PAGE, HCP and residual DNA. AVIPure AAV2 Resin delivered purified product with 7-fold lower residual HCP, 1.5X lower residual DNA and fewer impurity proteins by SDS-PAGE.

Results

AVIPure® AAV2 Resin delivered purified product with 7-fold lower residual HCP.

AVIPure® AAV2 Resin delivered purified product with 1.5X lower residual DNA and fewer impurity proteins by SDS-PAGE.

SPEED TO MARKET

SPEED TO MARKET

Available pre-packed in OPUS® Columns for quick deployment

AVIPure® AAV affinity resins are available in pre-packed and pre-qualified OPUS® Columns for rapid GMP implementation as well as in loose resin formats.

OPUS® Columns allow you to progress from development to manufacturing scale in weeks, using pre-packed and pre-qualified chromatography columns.

AVIPure® AAV2, 5, 8, 9 Resin characteristics

|

Category |

Description |

|---|---|

| Base Matrix | Cross-linked agarose, spherical |

| Particle size (d50V) | ~ 50 µm |

| Ligand |

AAV2, AAV5, AAV8: Alkali-tolerant recombinant protein (animal free) AAV9: Alkali-tolerant, peptide (synthetic) |

| Coupling chemistry |

AAV2: Thiol |

| Binding capacity |

High dynamic binding capacity even at short residence time enables use with pre-concentrated feed or direct capture: |

| Buffer compatibility | Stable to all commonly used aqueous buffers, including 8 M urea, 6 M guanidine hydrochloride, ethylene glycol, and detergents |

| Solvent compatibility | Water, alcohol (0–20% v/v), acetonitrile, 1–2 M acetic acid, other common organic solvents |

| pH stability | 1-13 |

| Cleaning-in-place stability | 0.1-0.5 M NaOH |

| Pressure/flowa | 3 bar at >300 cm/hr |

| Maximum pressure (ΔP)a | 40 psi |

| Temperature stability | 2–40 °C |

| Delivery conditions | 2% benzyl alcohol |

| Storage | 2–8 °C, 2% benzyl alcohol or 18-20% ethanol; do not freeze |

| a In a 2.6 x 20 cm column pressure packed at 4 bar |

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers