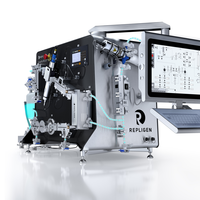

KrosFlo® FS TFF Systems

Fully automate flat sheet TFF processes up to 500 L with configurable hardware components that deliver an unparalleled combination of automation, configurability, simplicity and compliance.

Scalable

Scale from Lab to Pilot manufacturing

integrated

integrated

Modular, plug-and-play hardware with diaphragm pump

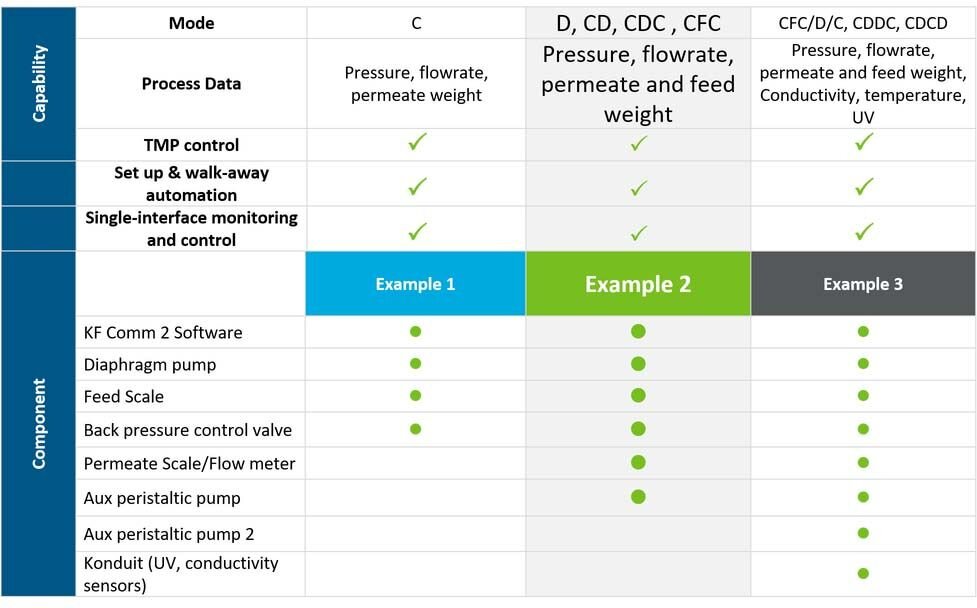

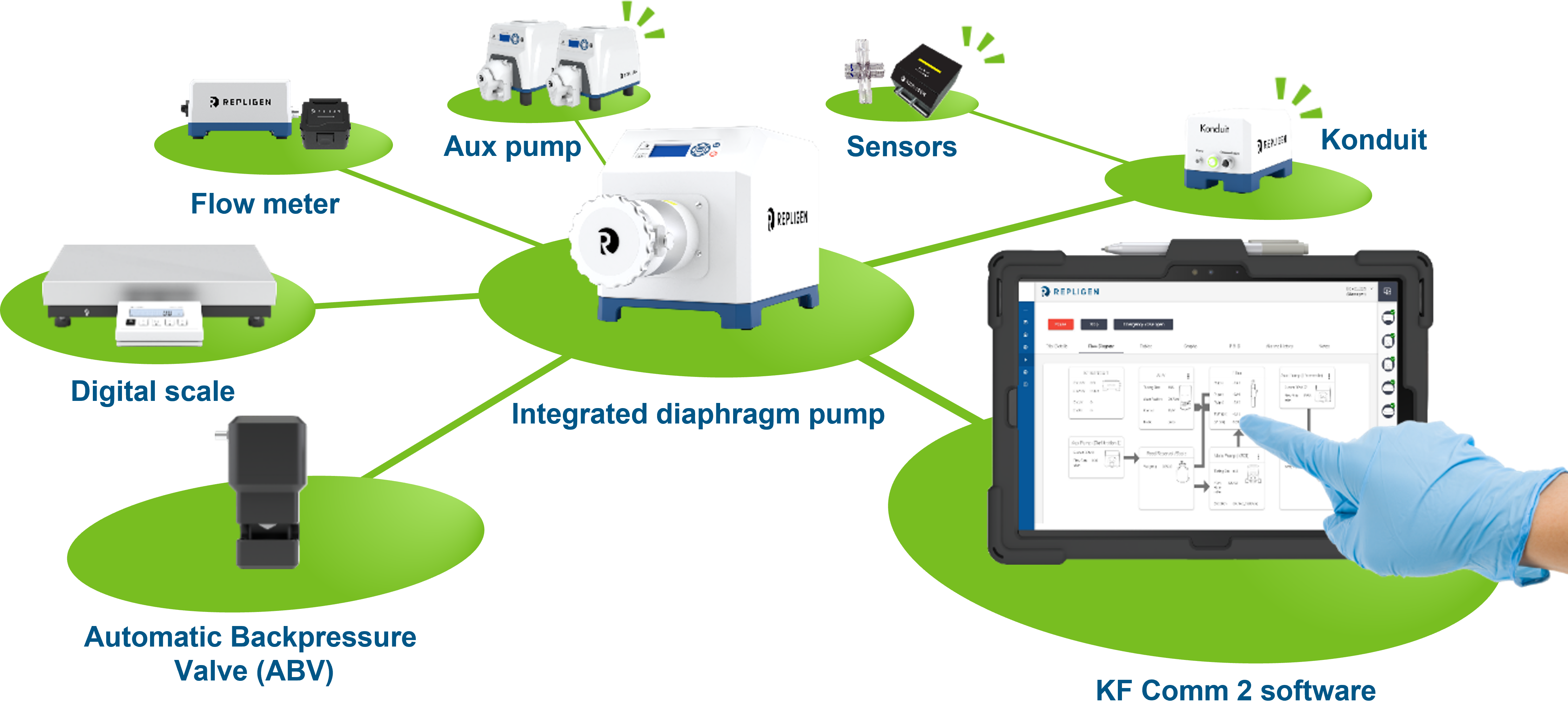

The KrosFlo® FS Systems achieve an unparalleled combination of configurability and automation and compliance for flat sheet TFF processes. All components, either directly or indirectly, connect to the main KrosFlo® FS diaphragm pump, which then communicates with the KF Comm 2 software for control and monitoring.

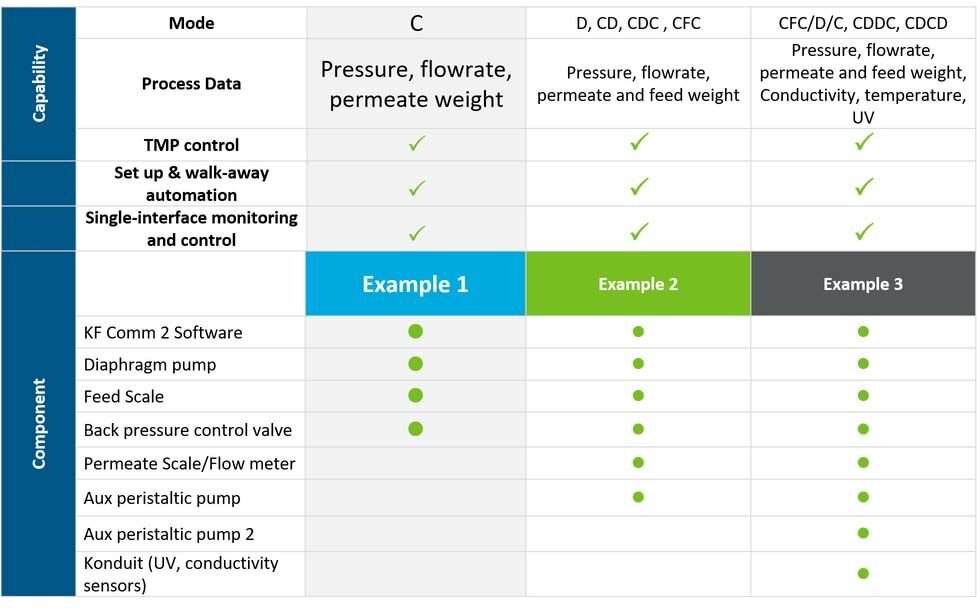

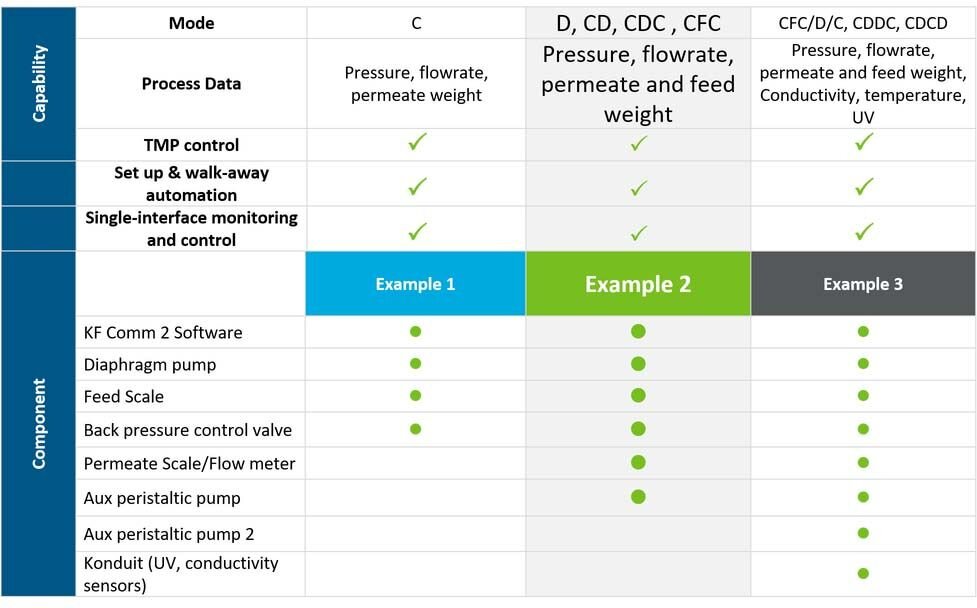

- Configure a minimal number of components for simple applications such as concentration (C) or diafiltration (D)

- Plug-and-play additional components for fractionation (F) and multi-step processes (i.e. CDC/D/C)

Click on the tabs below to explore different combinations of concentration and diafiltration configurations using the KrosFlo® FS TFF System.

C = Concentration D = Diafiltration F = Feed

Add a scale and auxiliary pump to access diafiltration applications

C = Concentration D = Diafiltration F = Feed

Build process understanding with increased sensors

C = Concentration D = Diafiltration F = Feed

integrated

integrated

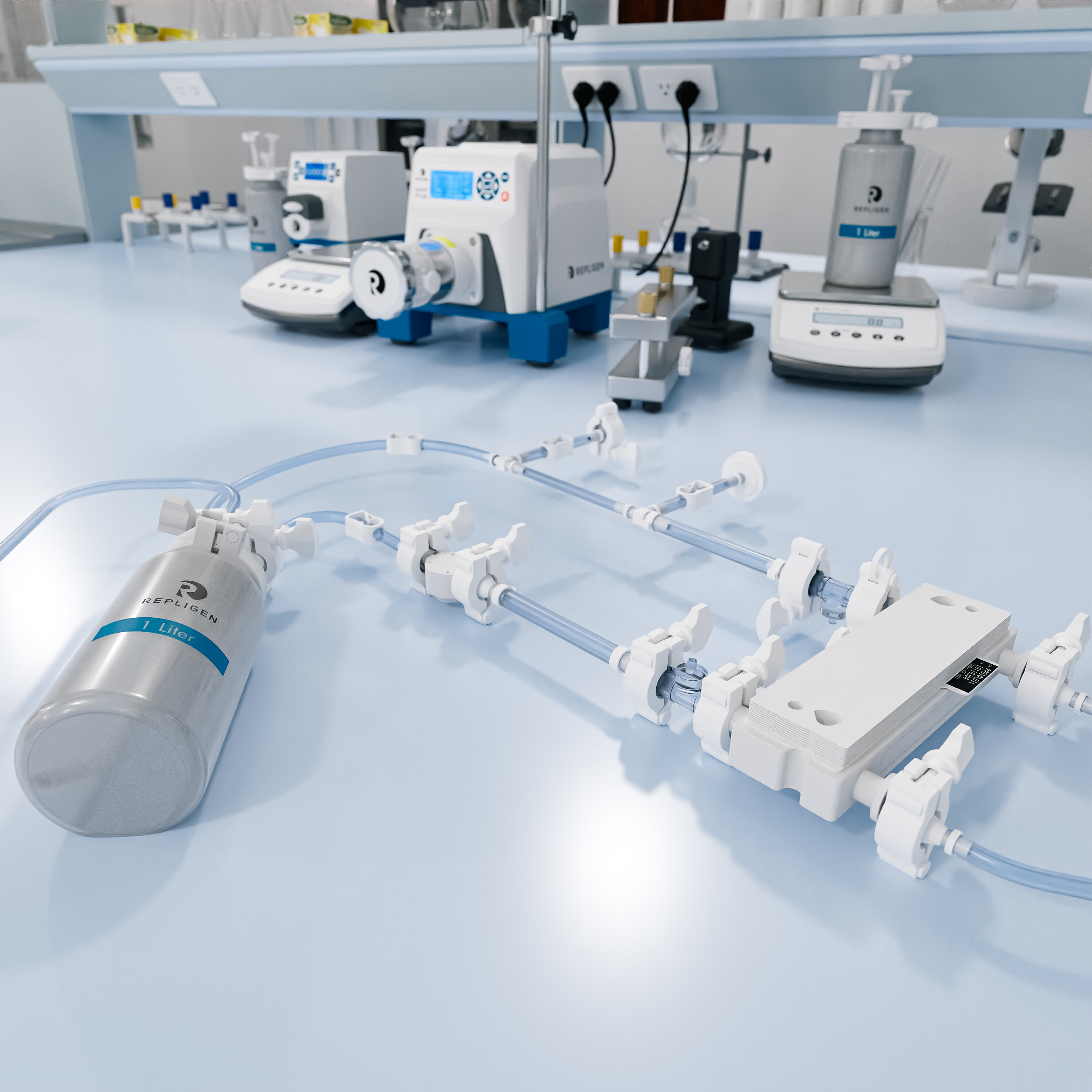

ProConnex® Flow Paths for FS Systems

Save time, streamline operations and hit the ground running

These ready-to-go flow paths create time and quality gains for every run. Enjoy the affordable convenience of off-the-shelf flow paths designed by the engineers who created the system you adore. These are created specifically to run TangenX® flat sheet cassettes on the KrosFlo® FS systems. Filter sold separately.

integrated

integrated

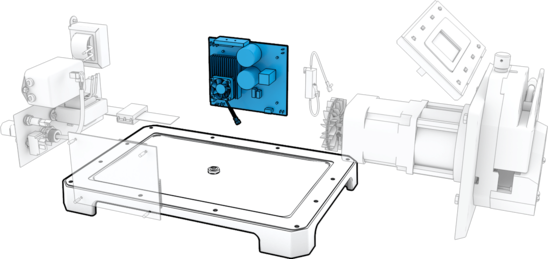

Transfer bi-directional data through

proprietary board

An advanced microprocessor-based controller is integrated into the main KrosFlo® FS System pumps, enabling plug-and-play hardware component behavior. Bi-directional communication is established between the KF Comm 2 software and hardware components, such as the Automatic Back Pressure Control Valve, scales, auxiliary pumps and the Konduit device.

KrosFlo® KR2i TFF System Virtual Demo Series

In this 6-part series, Simon Detzner provides viewers with a virtual training on the KrosFlo® KR2i TFF system. This training series will cover the following topics:

- Introduction to system components

- Installation of flow-path and filter

- KF Comm2 software overview

- Recipe creation

- Running a CFC/D/C experiment

- Recovery of product

- BONUS: Flat Sheet Cassette Installation

AUTOMATED

AUTOMATED

KF Comm 2 Software, backward compatible with legacy KrosFlo® KR2i and KrosFlo® KMPi Systems, is conveniently installed on any computer using the Windows Operating System. The software is compatible with Chrome, Mozilla, Firefox and Microsoft Explorer browsers and is always current with automatic software and firmware updates.

- Proprietary software optimized for KrosFlo® TFF Systems

- Validated for GMP Processes with optional 21 CFR Part 11 option

- Intuitive workflow with 13 modes of operation

AUTOMATED

AUTOMATED

Automatic Back Pressure Control Valve

A Repligen-exclusive technology, the Automatic Back Pressure Control Valve adds transmembrane pressure (TMP) control to every TFF process, reducing operator hands-on-time and improving process reproducibility.

- Automatically adjust tubing pinch distance according to user-defined set-points

- Maintain uniform TMP throughout process run, decreasing membrane fouling

- Control permeate pressure and flow during microfiltration applications

- Use with compatible tubing sizes 13, 14, 16, 25, HP15, 17, HP24, 18, HP35, 36, and HP36

- Activate automatically using inlet, retentate, permeate or transmembrane pressures

AUTOMATED

AUTOMATED

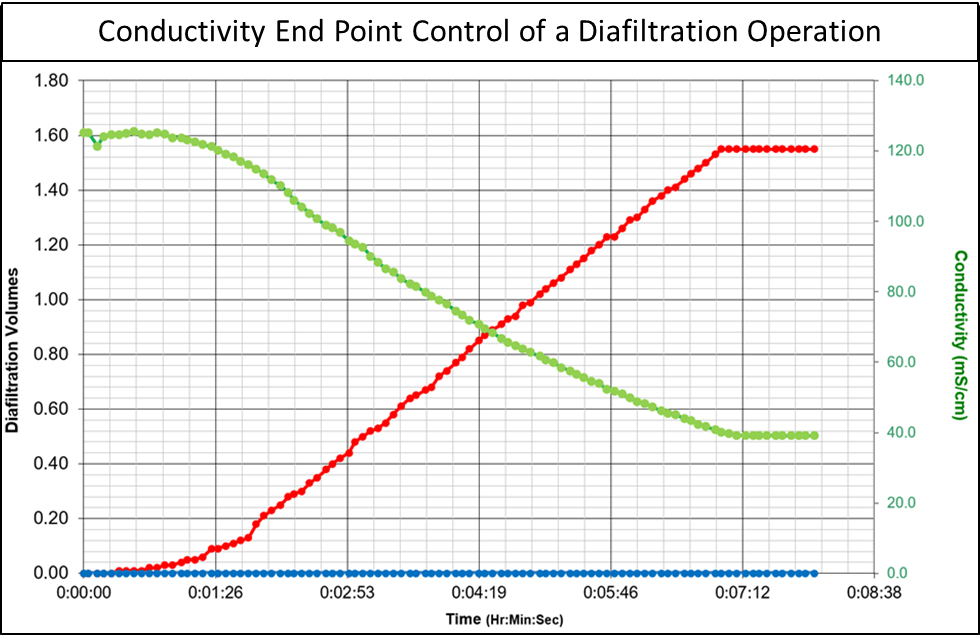

Monitor and evaluate conductivity, UV and temperature

Konduit is an add-on module ready to use with the KrosFlo® KR2i and KMPi TFF Systems, with the ability to scale from 2mL to 500L process volumes.

READY TO SCALE FAST

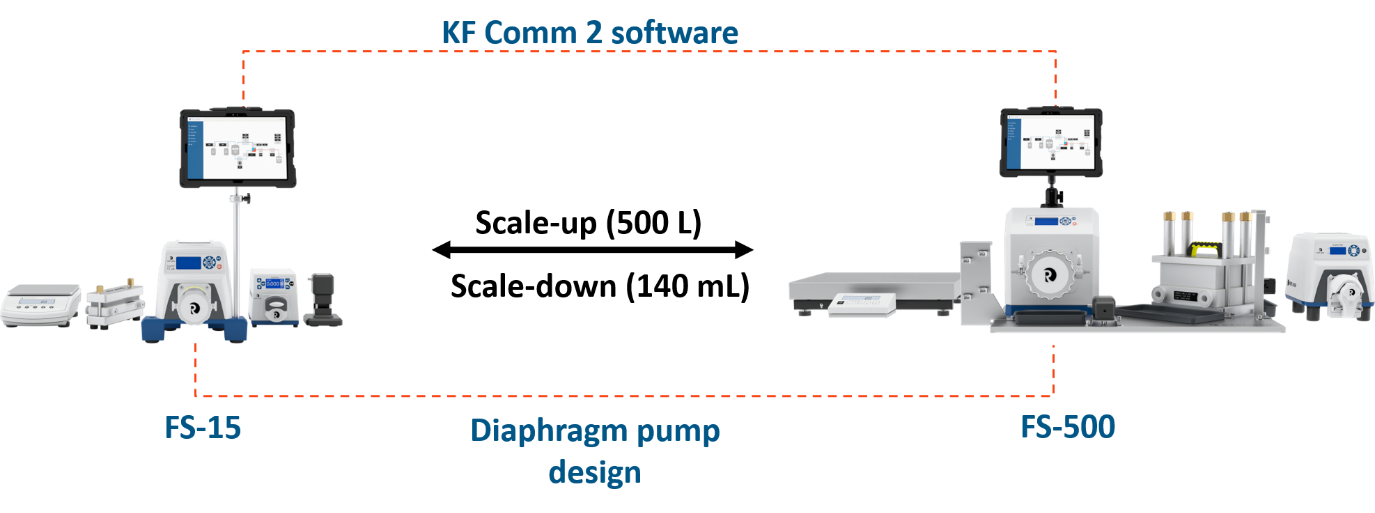

Scale effortlessly from Lab to Pilot Manufacturing

Transition seamlessly from small scale to larger scale processes. The KrosFlo® FS-15 handles volumes as small as 140 mL to 15 L. The KrosFlo® FS-500 is capable of larger volumes from 1.25 L to 500 L. These two KrosFlo® FS TFF Systems share common hardware architecture, software and pump technology.

- Scale-up and scale-down with a single platform

- Configurable across applications (C, D and CFC/D/C)

- Operate 21 CFR Part 11 compliant software built on secure Microsoft® SQL Server

KrosFlo® FS TFF Systems

The fully integrated KrosFlo® FS TFF System consists of hardware, software and flow path components. Key hardware components include: a diaphragm pump, auxiliary pumps and an automatic back pressure valve.

The KF Comm 2 software features a multi-language interface for complete monitoring and control and an optional 21 CFR Part 11 environment. Add tubing and sanitize/sterilize your own flow path around a Spectrum® hollow fiber filter or build a closed and gamma-irradiated ProConnex® Flow Path from over 250 components.

Click on the tabs below to explore features of the different systems.

140 mL - 15 L volume

0.1 - 0.3 m2 filtration area

KrosFlo® FS-15 compiles all the key features required for true walk-away automation and modernization of flat sheet processes from 140 mL up to 15 L, supporting membrane surface area from 0.1 - 0.3 m2. KrosFlo® FS-15 utilizes a Quattroflow™ 150 SU diaphragm pump delivering flow rates up to 3.0 liters per minute (LPM) and allowing for high pressure applications up to 4 bar.

Click on the links to explore different features.

1.25 L - 500 L volume

0.5 - 1.5 m2 filtration area

KrosFlo® FS-500 enables true walk-away automation and modernization of flat sheet processes from 1.25 L up to 500 L, supporting membrane surface area from 0.5 -1.5 m2. KrosFlo® FS-500 centers around a Quattroflow™ QF1200 SU diaphragm pump which delivers flow rates up to 18 LPM and allows for high pressure applications up to 4 bar. The KrosFlo® FS-500 design also utilizes a base plate for optimum flow path length and component geometry, as well as a permeate side flow meter.

Click on the links to explore different features.

Plug, play, walk away

Truly automate simple to multi-step TFF at 140 mL - 500 L and just…walk away.

Components and Accessories

Konduit adds:

- End point conductivity control for UF /DF

- End point UV control for diafiltering free drug from drug delivery particles

- End point UV control for concentration of certain molecules

- UV alarm for membrane breakthrough

- A260 and A280 light sources available

KrosFlo® KR1 Auxiliary Pump

Auxiliary pumps automatically increase or decrease buffer/product addition to feed reservoir.

KrosFlo® KR Jr Auxiliary Pump

Auxiliary pumps automatically increase or decrease buffer/product addition to feed reservoir.

Scales

Maintain user-defined feed weight set-points, and total permeate mass during TFF processes.

Transducers

- Measures and displays 4 pressures: Feed Pressure, Retentate Pressure, Permeate Pressure, Transmembrane Pressure (TMP)

- User-defined pressure alarms and stop set-points

- Available with different connector types (Luer and TC) and selected materials of construction (PS, PC)

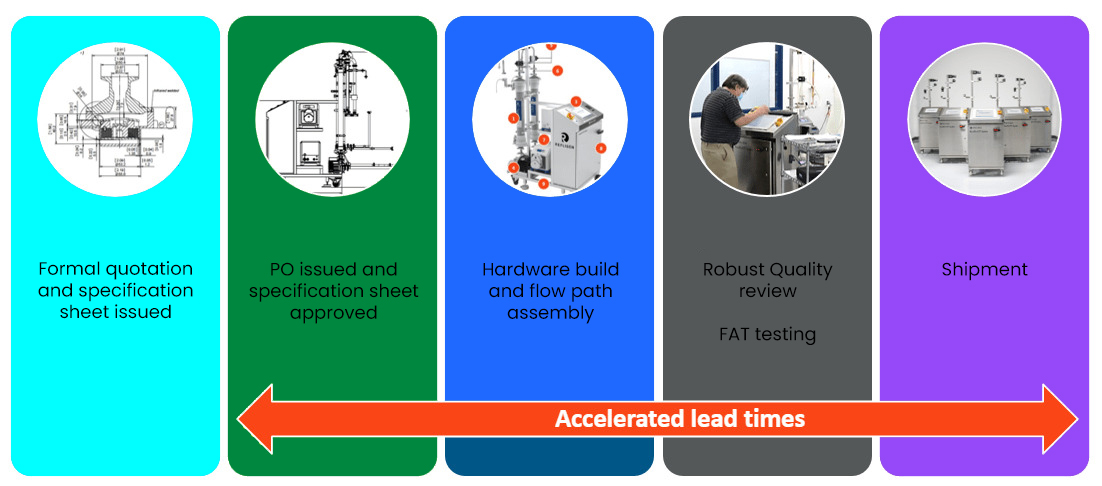

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.

Expert Project Management

Customer First.

Support is part of the Repligen DNA. Our goal is to provide exceptional customer experience, and to support the efficient and successful adoption and implementation of all Repligen products and services.

- Field Application Support

- Customer Service

- Field Service Engineers

Resources

Specifications

|

KrosFlo® FS-15 |

KrosFlo® FS-500 |

|

|---|---|---|

| Typical process volumes | Up to 15 L+ | Up to 500 L+ |

| Maximum filter area | Up to 0.3 m2 | Up to 1.5 m2 |

| Maximum Pressure | Up to 60 psi/4 bar | |

| Flow rate | Up to 3 LPM | Up to 18 LPM |

| Cassette holder | TangenX® SIUS® PD Clamp | TangenX® SIUS® Clamp |

| Reservoirs | 1 L PP, Ported Flat Bottom | 20 L PP, Ported Flat bottom |

| Mixing | Stir plate mounted on scale | |

| TMP Control | Non-invasive/No-product contact | |

| Auxiliary pump | KrosFlo® KRJr | KR1 |

| Flow Path | ProConnex® Flow Path - Single-use high pressure flow path with pump head | |

| Software |

KF Comm 2 with optional 21CFR part 11 package |