Hollow Fiber Filters

Ideal for ultrafiltration and microfiltration of shear-sensitive modalities, Spectrum® Hollow Fiber Filters for TFF can accommodate the widest range of scales, membrane chemistries and pore sizes to maximize process outcomes.

Maximized performance

Gentle on shear-sensitive product

Emphasis on Efficiency

Enhance AAV Purification with Optimal Hollow Fiber Membrane Selection

Discover how 100kD mPES Spectrum® Hollow Fiber Filters outperform standard PS membranes by reducing processing time, boosting efficiency, and maximizing recovery.

- Up to 38% Faster Processing: Spectrum® mPES membranes reduce AAV9 UF/DF run time by nearly 38% compared to competitor PS membrane

- 3x Higher Water Permeability: Enable higher potential flux and more efficient filtration

- >95% Product Recovery: Maintain viral yield, outperforming the ~65% recovery of competitor PS membranes

MAXIMIZED PERFORMANCE

MAXIMIZED PERFORMANCE

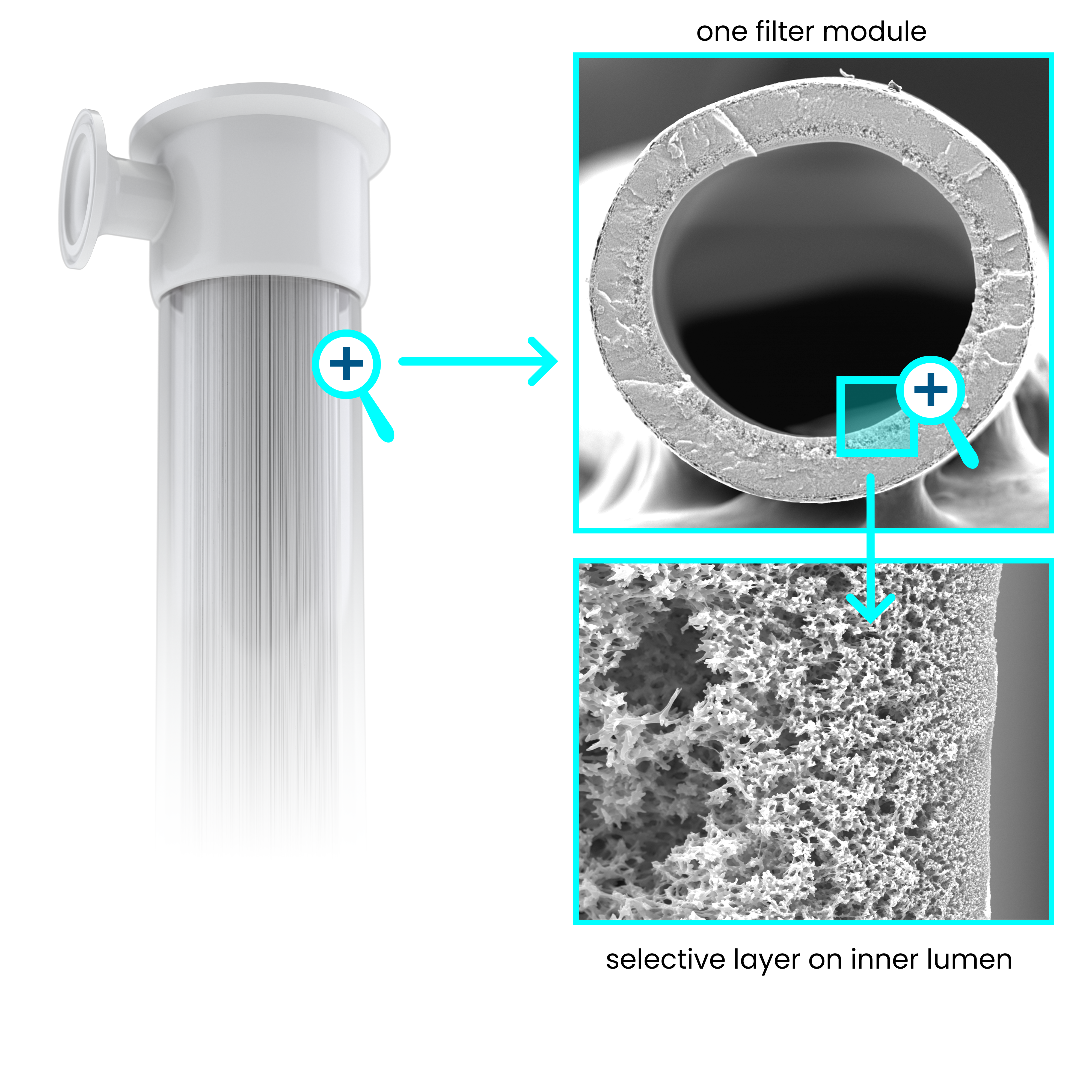

Game-changing mPES Chemistry

Directly modified from the PES backbone

- Uniquely formulated to provide tight selectivity without sacrificing high flux

- Thin selective layer in the inner lumen

- Significantly s more porous membrane

- Robust design for high-pressure applications

- Ideal for Lentivirus, mRNA, pDNA and LNPs

- Maximizes recovery

- Reduces fouling

Find your filter configuration Request a Quote

Membrane Applications

The following table shows typical use of membrane chemistries by application.

EMPHASIS ON EFFICIENCY

EMPHASIS ON EFFICIENCY

Emphasis on manufacturing innovation and security of supply

State-of-the-art facility

- ISO 9001 certified

- ISO 7 cleanroom

High degree of automation

- Hight throughput

- Consistency in quality

Competitive lead times

- Select off-the-shelf filters

- Available with or without gamma irradiation

END-TO-END EXPERTISE

END-TO-END EXPERTISE

Leverage TFF expertise in filter selection and beyond

- Selection of TFF format: Heavily reliant on modality

- Screening membrane MWCO: Selection based on recovery and impurity removal

- Final TFF condition optimization and sizing for process scale-up: Flux optimization and sizing at different scales

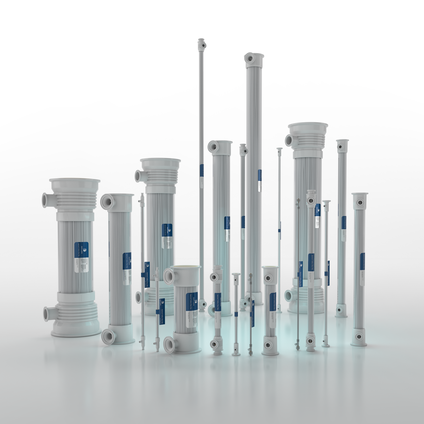

Scale-up made easy

Hollow fiber filter TFF modules are offered with a broad range of sizes, surface areas and membrane chemistries designed to facilitate easy scale-up from small volume process development and R&D applications to commercial production. During scale-up, adding more fibers to process larger volumes enables consistency in the length of the filtration flow path even while the surface area of the filter is increased.

| Primary Application | Volume | Inlet/ Outlet | Side Port | Effective Length (cm) | Total Length (cm) | Surface area | |

|---|---|---|---|---|---|---|---|

MicroKros |

|||||||

|

|

Process characterization, Small-volume TFF in a laboratory | 1-100 ml | MLL | FLL | 20 41.5 65 |

25 45 69 |

13 – 20 cm2 26 - 59 cm2 41 - 92 cm2 |

MidiKros |

|||||||

|

|

Process development at small scale | 100 ml - 3 L | FLL | FLL | 20 41.5 65 |

25 45 69 |

75 – 190 cm2 155 - 390 cm2 245 - 610 cm2 |

MidiKros TC |

|||||||

|

|

Process development at pilot scale | 100 ml - 3 L | 1/2" TC | FLL | 20 41.5 65 |

25 45 69 |

75 – 190 cm2 155 - 390 cm2 245 - 610 cm2 |

MiniKros Sampler |

|||||||

|

|

Batch TFF of small volumes | 3 L -15 L | 0.75" TC | 0.75" TC | 20 41.5 65 |

25 47 70 |

490 – 1000 cm2 1000 - 2200 cm2 1600 - 3400 cm2 |

MiniKros |

|||||||

|

|

Pilot-scale TFF | 5 L - 50 L | 1.5" TC | 0.75" TC | 20 41.5 65 |

25 46 70 |

0.16 - 0.31 m2 0.32 - 0.65 m2 0.51 - 1.0 m2 |

KrosFlo® |

|||||||

|

|

Production-scale TFF | 10 – 100L | 3" TC | 1.5" TC | 20 41.5 65 |

23 46 69 |

0.78 - 1.6 m2 1.65 - 3.25 m2 2.55 - 5.10 m2 |

KrosFlo® MAX |

|||||||

Request a Quote Request a Quote |

Production-scale TFF | 100L – 1000+L | 6" TC | 1.5" TC | 49.9 67.9 107.5 |

73.5 91.5 131.1 |

4.30 - 10.40 m2 7.10 - 17.10 m2 11.30 - 11.35 m2 |

Configurators

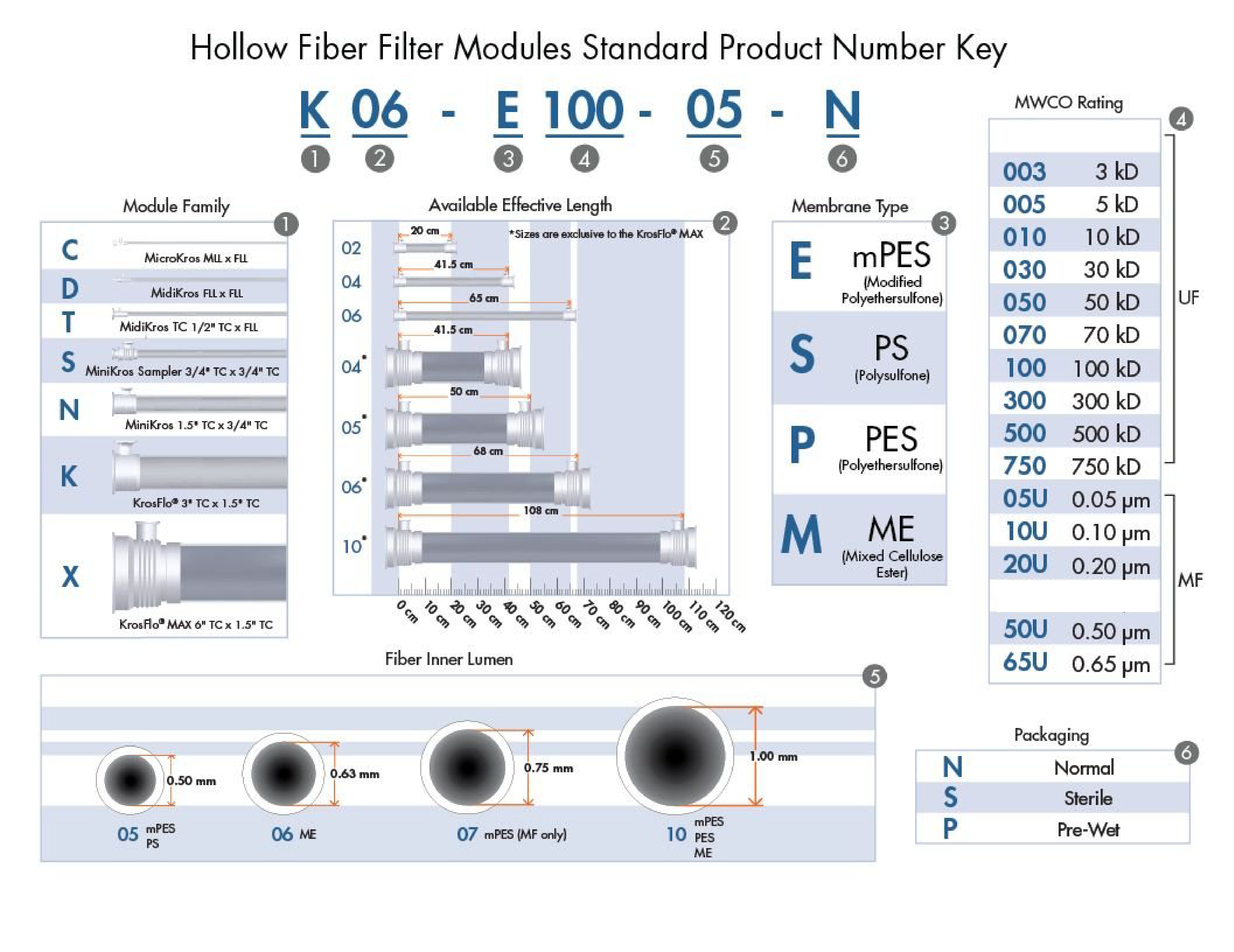

Product Number Key

To specify the hollow fiber filter specific to your application, follow the product number key below.

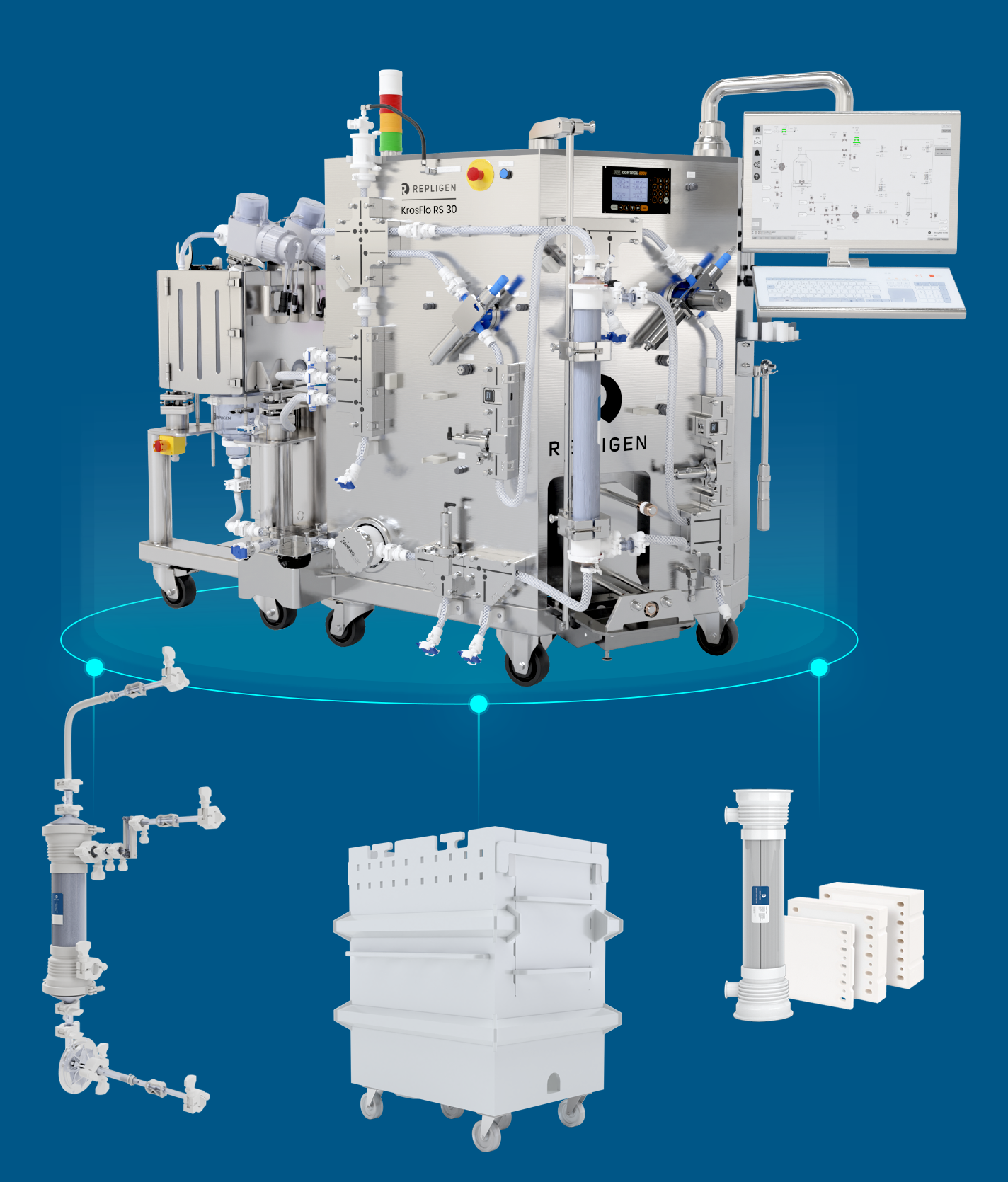

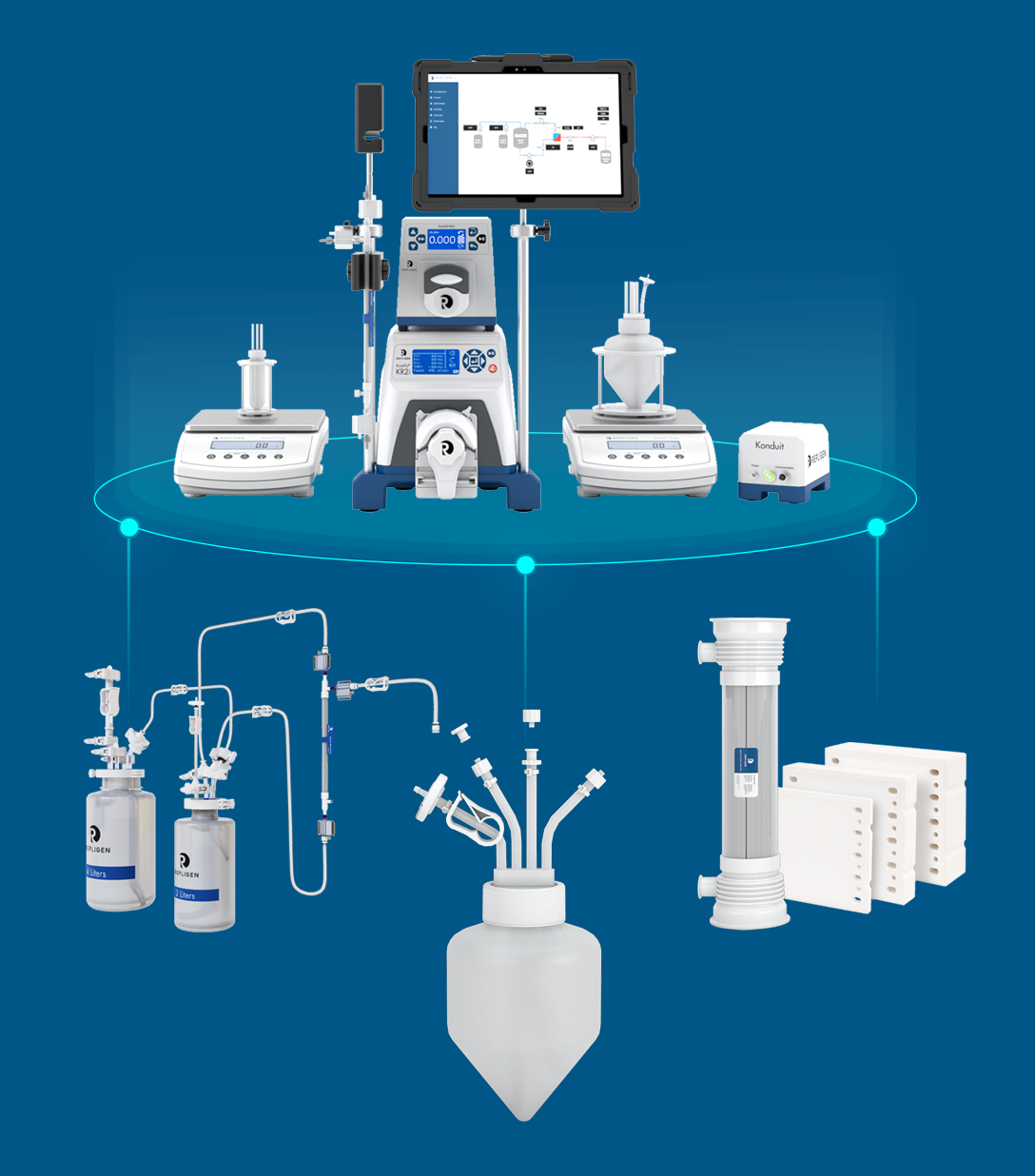

Click on the image highlights to see the different elements of lab-scale and commercial-scale TFF Solutions from Repligen

Complete lab-scale TFF Solution from Repligen

Complete commercial-scale TFF Solution from Repligen