Optimize Downstream Processing

Improve process productivity and facility efficiency

At Repligen, we are revolutionizing the way biotherapeutics are manufactured. Our advanced downstream processing solutions are designed to maximize process productivity, enhance facility efficiency, and help you deliver life-changing therapies with confidence. Discover how our innovative product lines can transform your operations.

Tangential Flow Filtration (TFF) Solutions Designed for Your Workflow

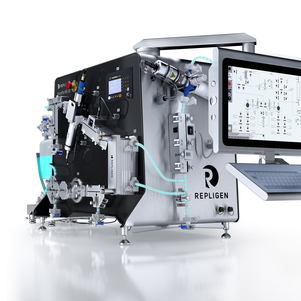

KrosFlo® TFF Systems

Repligen’s KrosFlo® TFF systems are trusted for their precision and scalability. Designed to streamline ultrafiltration and diafiltration (UF/DF) processes, these systems provide:

- High throughput with minimal product loss

- Superior automation for consistent performance

- Scalability from lab-scale to GMP production

TangenX® Flat Sheet Cassettes

Achieve exceptional performance in your TFF processes with TangenX® Flat Sheet cassettes. These advanced cassettes and holderless devices are engineered for:

- Superior selectivity and product recovery

- Rapid installation and scalability

- Cost efficiency through reduced fouling and cleaning requirements

Spectrum® Hollow Fiber Filters

Maximize the efficiency of your filtration process with Spectrum® Hollow Fiber Filters, designed for:

- High flux and low shear to protect sensitive biologics

- Easy scalability from lab to production

- Tight selectivity that delivers consistent performance

Single-Use Flow Path and Fluid Management Solutions

From ready-to-use flow paths designed specifically for use on our downstream systems to a fully customized assembly, single-use fluid management solutions support:

- Flexible, single-use configurations

- Sterile and secure fluid transfer, containment, and mixing

- Reduced setup and downtime

Real-Time Process Management Systems

Experience unparalleled control and optimization of ultrafiltration/diafiltration (UF/DF) process with RPM™ TFF Systems. These advanced systems provide:

- Real-Time concentration measurement provides accurate readings directly within the process stream, enabling continuous monitoring throughout the UF/DF process. Automated process control adjusts process parameters based on real-time concentration, ensuring precise control and optimization throughout the UF/DF to achieve desired target concentration every time

Optimized efficiency and quality using PAT-driven control to ensure optimal efficiency and product quality, reducing processing time and minimizing product variability.

Chromatography Solutions Tailored to Your Needs

KRM™ Chromatography Systems

Our KRM™ chromatography systems offer a high level of automation and efficiency for:

- Consistent separation with minimal manual intervention

- Precise process control through advanced automation

- Scalability across all production stages

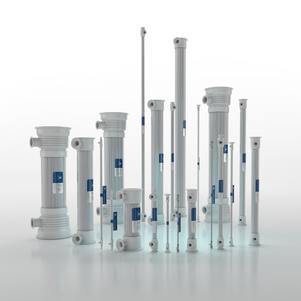

OPUS® Pre-packed Chromatography Columns

OPUS® columns are ready-to-use and customizable, delivering:

- Consistent performance and reduced risk

- Improved facility efficiency through simplified column preparation

- Flexibility for a wide range of biotherapeutics

Affinity Resins

Designed for precision and reliability, our affinity resins enable:

- High-purity and recovery of monoclonal antibodies, viral vectors and other modalities

- Consistent performance across batches

- Cost-effective with reusable formats

Real-Time Process Analytical Technology (PAT)

CTech™ SoloVPE® PLUS System (At-line/Off-line)

Unlock fast, accurate concentration measurements with reliable, dilution-free analysis, supporting high-quality performance across the bioprocessing workflow and in-demand applications

- Fast analysis delivers precise results in under 30 seconds

- Dilution-free measurement eliminates dilution errors and variability for more reliable results

- Reproducible results ensure consistent performance across systems, operators, and sites

CTech™ FlowVPX® System (In-line)

Achieve reliable real-time concentration measurements with seamless integration throughout every stage of the downstream GMP process. This cutting-edge system offers:

- Increase process understanding to accelerate product-to-market

- Reduce cycling time by eliminating delays associated with off-line testing

- Minimize risk with continuous monitoring throughout the process

Why Choose Repligen?

Repligen’s commitment to innovation and quality ensures that our solutions not only meet but exceed the rigorous demands of biopharmaceutical manufacturing. By integrating our downstream processing solutions, you can:

- Boost productivity through streamlined workflows

- Enhance facility efficiency with space-saving, scalable technologies

- Ensure regulatory compliance with state-of-the-art monitoring tools

Ready to transform your downstream processes? Contact us today to learn more about our innovative solutions and how they can help you achieve operational excellence.

Fill out this form to connect with a downstream expert.