PATsmart™ Analytical Solutions

THE FUTURE OF BIOPROCESSING

From early process development to scale-up and manufacturing control, PATsmart™ Analytical Solutions offer process analytical technology (PAT) tools that complement your laboratory, your process, and your workflow needs, whether at-line or in-line, delivering results when it matters, in real time.

Actionable Data Right At Your Fingertips

In today’s complex bioprocessing environments, know what you’re working with at every stage of the workflow, with instruments that work for you. With PATsmart instruments that perform accurate protein characterization, rapid cell culture media analysis, and optimized UV-Vis–based protein analytics, we deliver immediate insights that power smarter decisions—enabling tighter process control and significantly reducing the risk of sample loss or lost operating time.

Designed for High-Value, High-Risk Bioprocesses

Whether you’re operating upstream or downstream, working with precious biological materials leaves little room for error. A single inaccurate measurement or delayed response can cascade into lost yield, costly process interruptions, or compromised product quality.

PATsmart™ solutions provide timely, reliable analytical insight at critical points in the workflow—enabling earlier detection of deviations, faster decision-making, and more precise process adjustments. By improving visibility into process performance, PATsmart solutions help teams use high-value materials more efficiently, reduce rework and waste, and protect both product yield and manufacturing assets.

Work Smarter, Not Harder

At Repligen, our goal is to ensure your bioprocess instruments work for you, not the other way around.

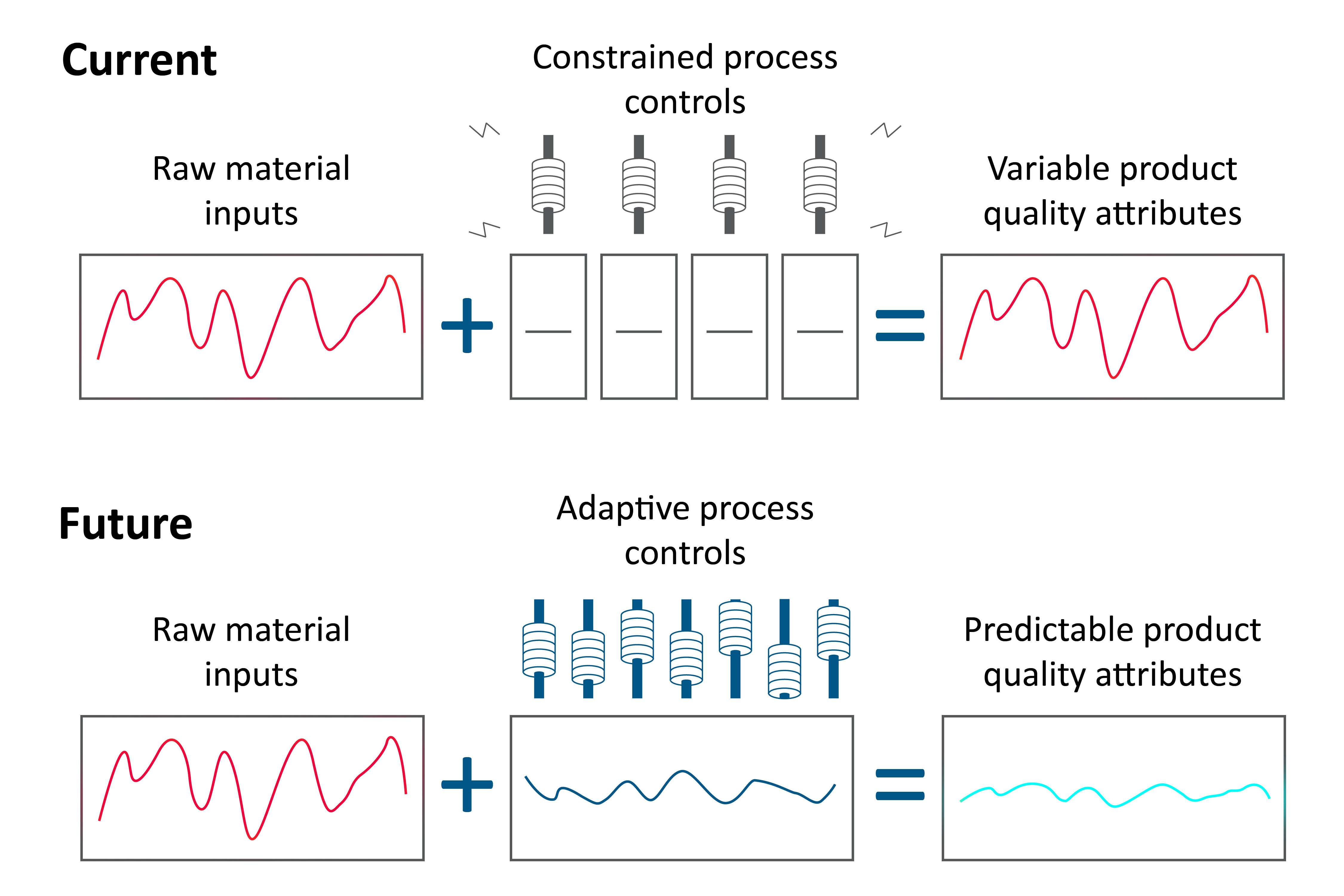

PATsmart Analytical Solutions are built upon the knowledge that complex, variable inputs are inherent in bioprocessing, and uninformed decisions can be costly. Our extensive portfolio of PATsmart technology provides adaptable and real-time process understanding, process monitoring, and process controls specifically for your needs. By implementing PATsmart technologies throughout the bioprocess workflow, you can achieve consistent quality, maximize product yield, and optimize manufacturing outcomes.

- Upstream and downstream critical process parameter (CPP) monitoring

Continuous insight without process interruption - Improved process control and reproducibility

Detect and correct deviations early - Reduced reliance on off-line or off-site testing

Save time, labor, and precious sample volume - Scalable across the bioprocess lifecycle

Suitable for process development, scale-up, and GMP manufacturing

We open a window into your process, so you can rest assured that your instruments perform at their highest level, while outputting highly reproducible results.

Smarter Cell Culture Media Analysis

Cell culture media is the foundation of biologics production—and it is often one of the most variable and difficult elements to control.

Through a combination of capillary electrophoresis and mass spectrometry, navigate the process of identifying amino acid and nutrient profiles that traditionally takes weeks, in just a few minutes.

PATsmart™ REBEL® XT offers timely insights into changes occurring during cell growth, by delivering advanced media analysis of 22 key analytes such as amino acids, dipeptides, and choline, in as little as 15 minutes and without sending it to a different lab—so you know exactly what to expect and when to expect it.

Skip the Setup, Get to the Data

Every PATsmart device is designed to operate as intuitively as possible, so you can seamlessly integrate your instrument into your existing bioprocess.

Instruments like the PATsmart™ MAVEN® System automate processes such as feeding strategy that require manual sampling and costly guesswork; through continuous glucose and lactate data every 2 minutes, the result is sustained cell growth, greater product yield, and reduced sample contamination and error risk.

With the PATsmart™ MAVERICK® Analyzer, get real-time, in-line data for glucose, lactate, and total biomass within minutes, without the time-consuming method development or modeling expertise normally required for Raman spectroscopy.

Find the model that works for you, and let it do the heavy lifting.

Smarter Control using Variable Pathlength Technology (VPT)

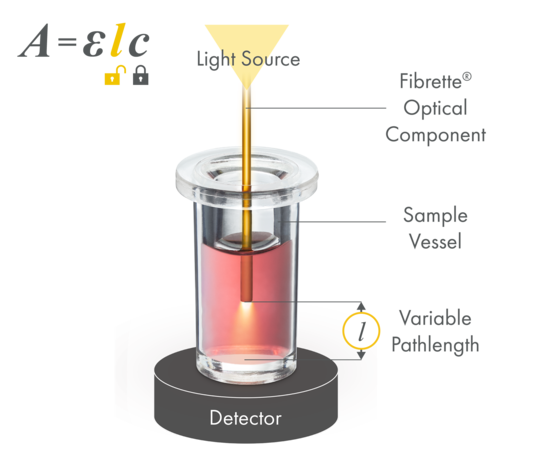

Variable Pathlength Technology (VPT) is an industry-changing, UV-Vis–based PATsmart™ technology that continues to redefine protein concentration measurement by enabling rapid, dilution-free analysis across a wide dynamic range.

By capturing multiple absorbance measurements per sample, VPT improves confidence in concentration results while delivering data in minutes rather than hours—providing timely insight that supports smarter decisions and more controlled bioprocesses across development and manufacturing.

The PATsmart™ SoloVPE® PLUS System applies VPT at-line to deliver fast, dilution-free protein concentration measurements without disrupting the workflow. Designed for process development, analytical development, and QC environments, SoloVPE® PLUS provides reliable concentration data in minutes—helping teams make faster, more informed decisions while conserving valuable sample material.

The PATsmart™ FlowVPX® System extends VPT in-line, providing continuous, real-time protein concentration monitoring directly within the process. By delivering immediate visibility during critical unit operations, FlowVPX® supports earlier detection of deviations and more informed process adjustments—without interrupting production—helping reduce risk and protect yield from development through manufacturing.

Zip to the Finish Line

Replace lengthy LC-MS runs with the PATsmart™ ZipChip® System—a microfluidic capillary electrophoresis device that you can install directly on your mass spectrometer to quickly and easily analyze critical quality attributes (CQA) measurements in under 10 minutes.

This compact device enables rapid protein characterization and metabolomic analysis using charge variant analysis, intact mass analysis, peptide mapping, and reduced/subunit analysis—all in one instrument!

The Smarter Way to Bioprocess

We want to arm you with the latest and most robust data you need to move confidently through your bioprocess. PATsmart Analytical Solutions deliver the insight and control needed to enable greater consistency, higher product quality, and reduced risk.

Don’t know where to start? Take the guesswork not just out of your bioprocess but your PATsmart implementation, by speaking to one of our experts.