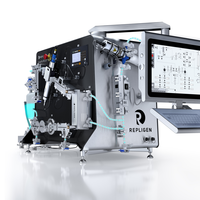

KrosFlo® KR2i TFF System

Single-use fully integrated benchtop TFF system for research and process development (PD) ranging from 2mL - 15L. Compatible with hollow fiber and flat sheet filters, this system features a peristaltic feed pump with 13 automated process modes.

Robust Processing

Ultrafiltration and diafiltration (UF/DF) processing for batch volumes ranging 2mL to 15L.

Easy to use

Plug and play configurability to add and remove components as needed with minimal effort.

Compatible with flat sheet cassettes and hollow fiber filters.

Modularity Made Easy with Plug-and-Play Configurability

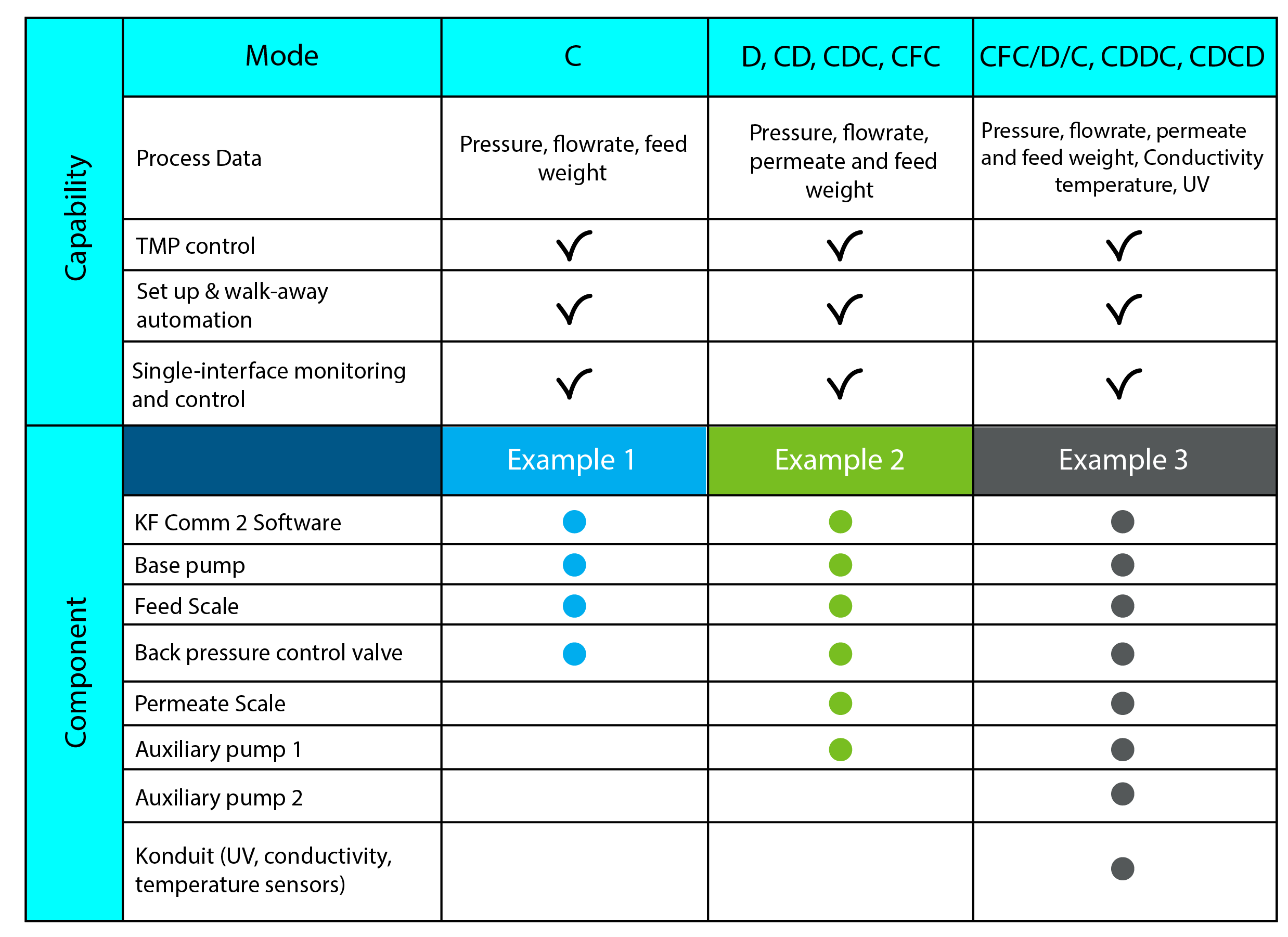

KrosFlo® KR2i TFF systems achieve an unparalleled combination of configurability and user-simplicity through modular, plug-and-play hardware. All components, either directly or indirectly, connect to the main pump, which then communicates with the KF Comm 2 software for control and monitoring.

More Capabilities, Still Simple.

Get more out of TFF with the flexibility to configure your system to better suit your application needs. Keep your process compact and minimal or expand your capabilities to more advance modes of operation by adding components. Switch back and forth between configurations all without compromising on ease of use.

Automate, Control and Visualize with KF Comm 2

Control the whole system, configure recipes and automate processes in as little as 4 clicks through the intuitive KF Comm 2 software.

- Conveniently installed on any device using the Windows Operating System

- Compatible with Chrome, Mozilla, Firefox and Microsoft Explorer browsers

- Automatic software and firmware updates

- Optional 21 CFR Part 11 package available

Still using legacy KF Comm software? Upgrade now

Walk-away automation for your lab

The days of manually adjusting screw clamps are over. A Repligen-exclusive technology, the Automatic Back Pressure (ABV) Valve adds transmembrane pressure (TMP) control to every TFF process, reducing operator hands-on-time, data logging and continuous monitoring while improving process reproducibility.

- Automatically adjust tubing pinch distance according to user-defined set-points

- Maintain uniform TMP throughout process run, decreasing membrane fouling

- Use with compatible tubing sizes 13, 14, 16, 25, HP15, 17, HP24, 18, HP35, 36, and HP36

TFF with In-Line Protein Concentration Management

No longer are you dependent solely on mass inputs and off-line fixed-pathlength UV-Vis spectrophotometers. Now, you can measure what truly matters in real-time with the KrosFlo® KR2i RPM™ System. Monitor concentration in real time during your UF/DF run and control your process.

KrosFlo® KR2i TFF System Virtual Demo Series

In this 6-part series, Simon Detzner provides viewers with a virtual training on the KrosFlo® KR2i TFF system. This training series will cover the following topics:

- Introduction to system components

- Installation of flow-path and filter

- KF Comm2 software overview

- Recipe creation

- Running a CFC/D/C experiment

- Recovery of product

- BONUS: Flat Sheet Cassette Installation

ProConnex® Flow Paths for KR2i

Designed for all stages of process development, ProConnex Flow Paths are engineered for efficiency, reproducibility and performance while keeping personal preference in mind. Choose from one of three options to start streamlining your TFF operations today:

- NEW ProConnex® TFF Self-Assembly Kits simplify early PD set-up. One flexible assembly kit has everything you need — just add a bottle, filter and go.

- ProConnex® Standard Flow Paths come fully assembled to minimize process variability, enhance sterility and save time.

- ProConnex® Custom Flow Paths are fully tailored to your process, pre-assembled, and gamma-irradiated—ideal for use in cGMP environments. Add a fully integrated Spectrum® Hollow Fiber Filter and you’re ready to plug and play instantly.

Available gamma-irradiated, endotoxin-free, and particulate-free.

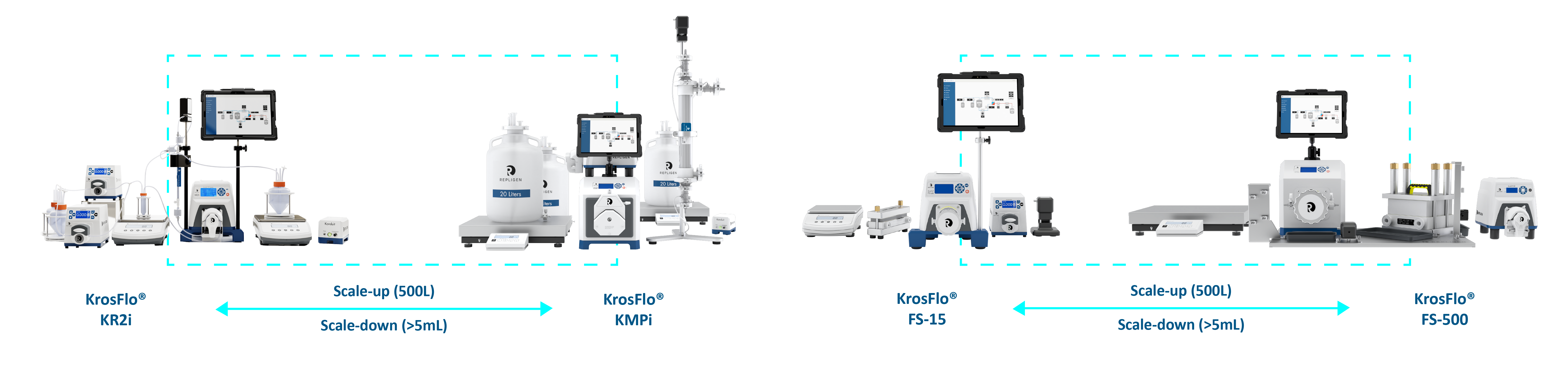

Effortless scaling with a single standardized platform

Designed as a platform and not as standalone units, KrosFlo KR2i, KMPi, and FS lab scale TFF systems share the same components, software and controls across the entire family, allowing you to confidently standardize your process. Common process change challenges during scale-up are removed.

System features at a glance

The fully integrated KrosFlo KR2i TFF System features a digital peristaltic pump, graphical LCD display, digital pressure monitor, KR2i Pump head, automatic backpressure valve, filter module stand, and KF Comm real-time data collection software.

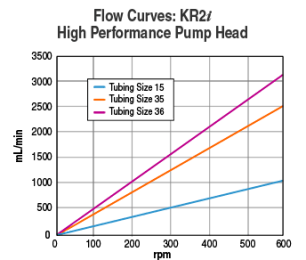

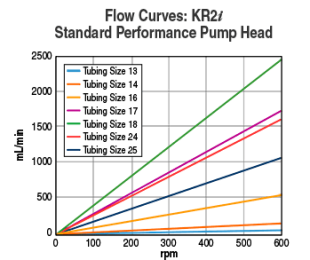

Highly configurable and versatile, the KrosFlo KR2i utilizes a number user-defined set-points to run complex application processes with numerous built-in safety alarms and stops. The system can run up to two stackable pump heads for higher flow rates.

Click on the links below to explore different features.

Components and Accessories

- IP 33 Enclosure

- 600 RPM pump with reversible drive

- 90-260 Vrms @ 50/60 Hz

- Standard Easy Load 3 Pump Head for precision tubing L/S number 13, 14, 16, 25, 17, and 18 provided.

- (Optional) Easy Load 3 pump head for high performance tubing L/S numbers 15, 24, 35, 36

- ETL listed and CE/UL/cUL marked

- Pump Drive Dimensions: 10.5 in x 8 in x 8 in

Konduit adds:

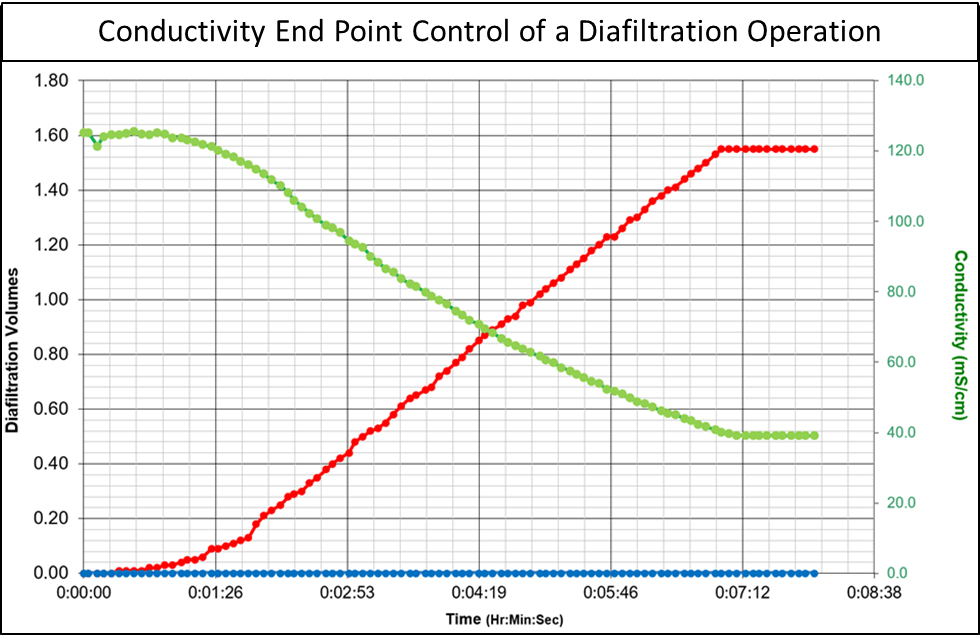

- End point conductivity control for UF /DF

- End point UV control for diafiltering free drug from drug delivery particles

- End point UV control for concentration of certain molecules

- UV alarm for membrane breakthrough

- A260 and A280 light sources available

Transducers

- Measures and displays 4 pressures: Feed Pressure, Retentate Pressure, Permeate Pressure, Transmembrane Pressure (TMP)

- User-defined pressure alarms and stop set-points

- Available with different connector types (Luer and TC) and selected materials of construction (PS, PC)