Videos

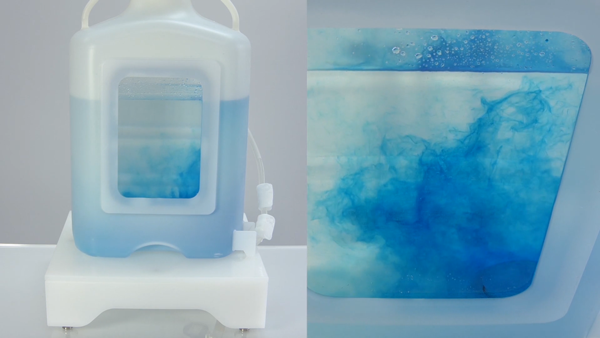

Even at very low speed. This video shows 2% of max power.

Bearing less design that does not need liquid to lubricate a bearing.

Mix up to 350 RPM in just a heartbeat.

All operational functions in one user friendly screen increasing operator efficiency and reducing the amount of training required.

Running a fully automated cGMP process has never been easier. From recipe upload to completion, the software is here to make sure you stay on track.

Your process outcome is only as good as your recipe. Whether its pre-configured templates or the flexibility to build from scratch- this recipe editor will help you succeed.

Learn how the inventors of TFDF™ (Tangential Flow Depth Filtration) technology nurtured the innovation from concept to commercialization. October 2019 | 3 minutes

See how the innovative diaphragm that controls alternating tangential flow in XCell ATF® Devices works. 1 minute

The XCell ATF® Device, a cell retention device available in single-use or stainless steel format attached to a bioreactor, delivers high cell density and process intensification. February 2019 | 4 minutes