KrosFlo® KTF TFF Systems

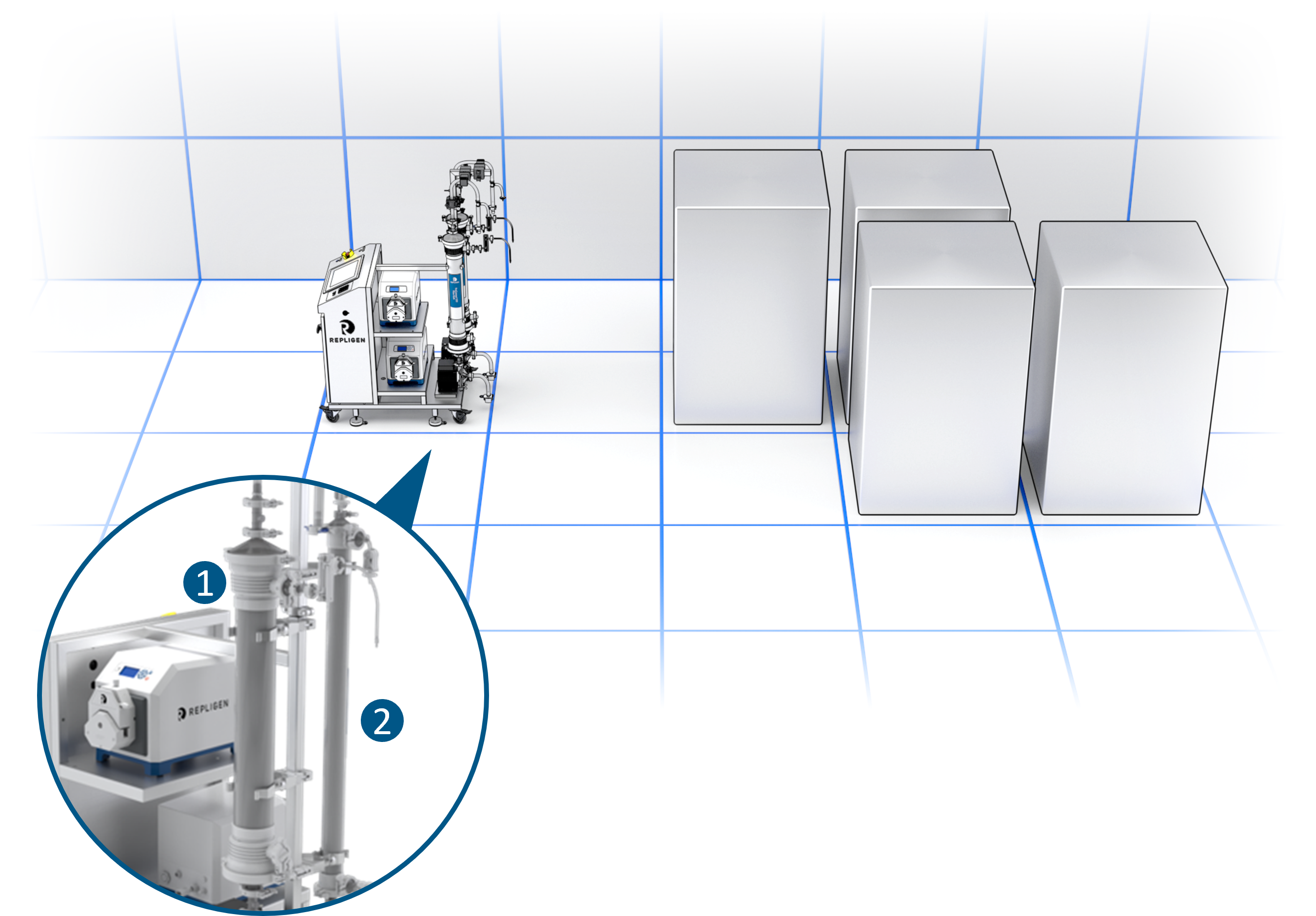

The KrosFlo KTF are a series of highly configurable single-use TFF systems for multiple unit operations, applications, and filter types. With volumes spanning across 1 to 5000L, users enjoy the unrivaled flexibility of processing large and small batch sizes within the same platform.

Unmatched configurability in one integrated system

The KrosFlo KTF is configurable across parameters like filter type (hollow fiber filters and cassette), feed pump sizes, filtration area, sensors and processing volumes- giving you the flexibility to custom build a TFF system that meets your specific needs.

Whether you’re working with shear sensitive modalities such as Lentivirus that require gentle processing or molecules like AAV that could benefit from the higher flux of a flat sheet cassette, the configurability and flexibility of the KTF system provides TFF solutions that enable you to do more.

Enhance your capabilities while retaining a small footprint

The dual pump design of the KTF enables you to use one system for two scales of TFF operations. By utilizing both pumps together for a single application, the system delivers twice the surface area, significantly higher than other offerings within the industry. This innovative design allows you to conserve valuable square footage and avoid multiple TFF skids by leveraging one TFF system for multiple unit operations, applications, and batch sizes.

One platform, multiple scales for unrivaled flexibility

With volumes spanning across 1 to 5000L, you can enjoy the unrivaled flexibility of processing large and small batch sizes within the same platform as well as the consistency during scale-up.

Even more capabilities, same small footprint: KrosFlo KTF +

We’ve taken the advanced technological capabilities of our premium line of TFF systems, KrosFlo RS series, to create the next generation of KTF systems. Enjoy all the benefits of our classic KTF system now with our new recipe-based software platform.

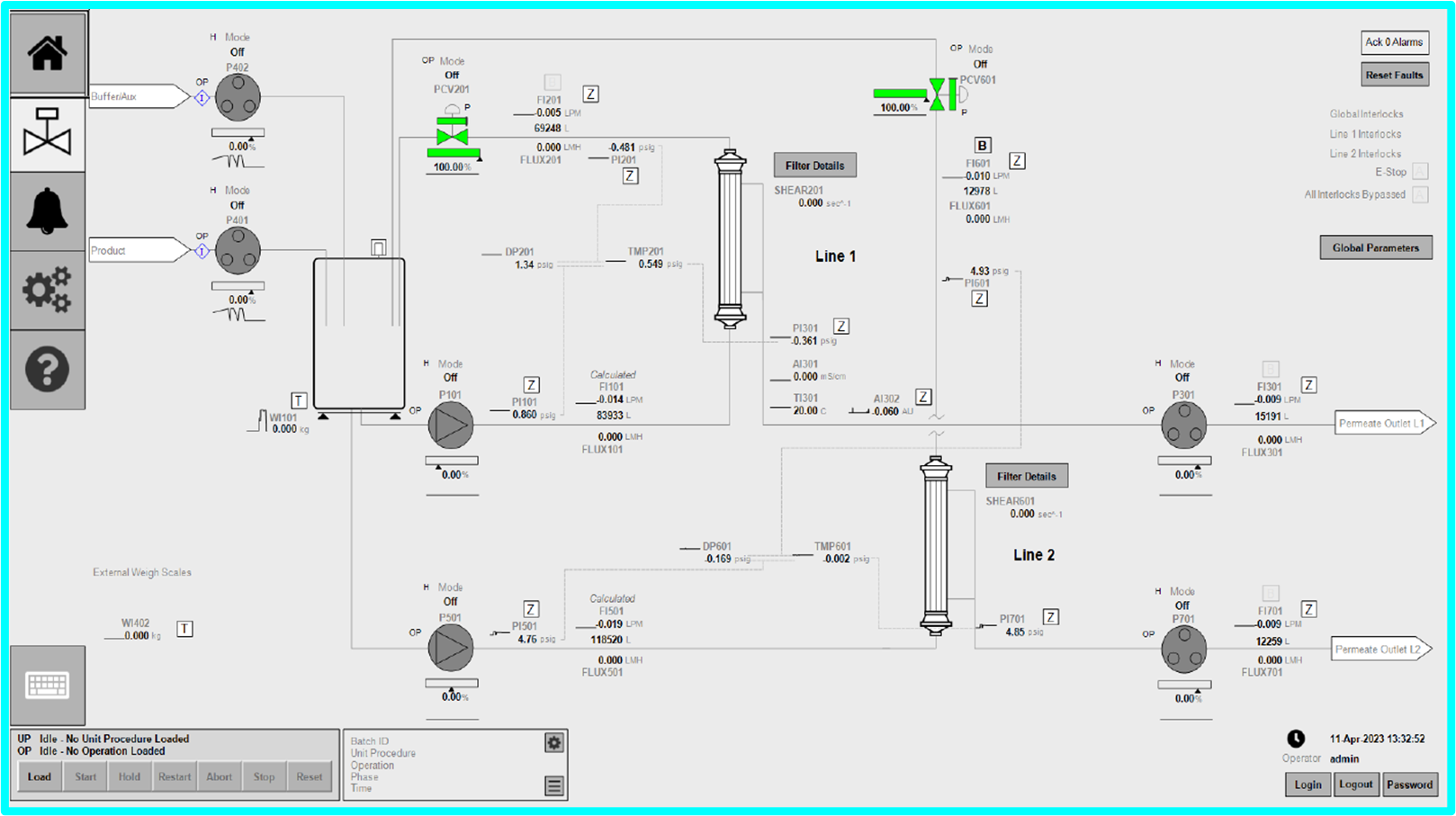

Unrivalled process control with KlariFi™

The KTF + is powered by the KlariFi™ system control software which features an intuitive P&ID user interface that matches the system hardware for easy navigation. The point and click editor enables recipe creation from scratch or customization from an extensive library of pre-built templates designed by TFF experts. Process data, batch records and trends are auto generated, stored, and secured with network integration and compliance top of mind.

KrosFlo® KTF TFF Systems

KrosFlo KTF Systems include filters, ProConnex® Flow Path, pumps, process monitors, software and graphic display on a single skid, with a small footprint.

Click on the links below to explore different features.

integrated

integrated

ProConnex® Flow Paths for KTF

ProConnex® Flow Paths for KTF prioritize process requirements and sterility. These flow paths by Repligen are customized, configurable and complete assemblies for tangential flow filtration at a larger scale. Designed for use with hollow fiber and/or flat sheet KTF configurations, the assemblies are sterile and manufactured in compliance with ISO guidelines in an ISO 7 clean room.

Manufacturing Centers of Excellence

Repligen develops and manufactures products for the biopharmaceutical industry under an ISO 9001 quality management system. We focus on the timely delivery of high quality, consistent and robust products, to ensure business continuity for our customers.

Repligen manufacturing sites are located in Massachusetts, California, and New Jersey in the United States and in Sweden, France, The Netherlands, Germany and Estonia.