Process Intensification

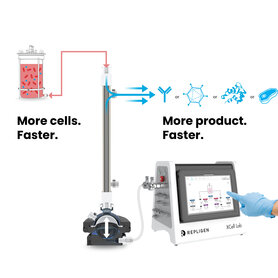

MORE. FASTER.

Bioprocess intensification is defined as a significant step increase in output relative to cell concentration, time, reactor volume or cost, resulting in improvements in productivity, environmental and economic metrics.

Bioprocess intensification usually involves a drastic change in equipment and/or process design e.g., moving from batch to continuous processing or integrating new process steps. The result is not only a considerable increase in productivity but a significant improvement in other environmental and economic metrics such as energy consumption, carbon footprint, OPEX and CAPEX.

Benefits of process intensification in bioprocessing

BUSINESS

- Miniaturized plant size

- Reduced CAPEX and OPEX

- Distributed manufacturing

- Faster from research to market

PROCESS

- Higher cell densities

- Increased productivity

- Improved product CQA

- Wider process conditions

- Continuous processing

ENVIRONMENT

- Reduced energy use

- Reduced waste

- Reduced reagent usage

- Smaller landscape footprint

Repligen solutions help overcome key challenges in process intensification, with hands-on process and implementation consultation from global Field Applications Specialists.

Leader in Upstream Process Intensification

Watch the webinars on history, potential, applications

The PAT landscape in upstream intensification, the benefits of this approach, and the scale-up from benchtop to manufacturing is discussed.

This webinar discusses similar efficiency gains for three different viral vectors (lentivirus, AAV8 and AAV9) through intensification using KrosFlo® TFDF® Technology that resulted in reduce train vessel number, N-1 vessel size, media volume and time.

15+ years of published application data, implementation in the largest number of commercial processes and proven scaling from 1 L to 5000 L differentiate XCell ATF® Technology from all other upstream intensification methods. Considerations for when and why to apply XCell ATF® Technology in order to meet specific productivity goals will be discussed.

03

03

Perfusion Cell Culture

Perfusion, a cornerstone of upstream continuous bioprocessing, has been practiced since the 1980s to maximize facility utilization, expand process flexibility and minimize costs. Today, novel cell retention devices and single-use technologies, with sophisticated control logic, simplify implementation.